Why Choose Robot Joints for Your Next Automation Project?

In the evolving landscape of automation, robot joints are becoming essential components. According to a report by MarketsandMarkets, the robotics market is projected to reach $73 billion by 2025. Among these innovations, robot joints play a crucial role in enhancing performance and flexibility. Industries are increasingly adopting these technologies to stay competitive.

Robot joints provide greater precision and adaptability in various applications. They facilitate smoother and faster movements, significantly improving workflow efficiency. Moreover, companies see a reduction in downtime and maintenance costs. Research indicates that integrating these joints can increase productivity by up to 30%. However, this transition is not without challenges. The initial investment for advanced robot joints can be high, leading some businesses to hesitate.

While robot joints offer numerous advantages, it’s vital to reflect on potential shortcomings. Not all projects require advanced joints, and sometimes simpler solutions suffice. Businesses must weigh the pros and cons, considering specific needs and budgets. Hence, the decision to choose robot joints should involve careful evaluation and planning.

Benefits of Using Robot Joints in Automation

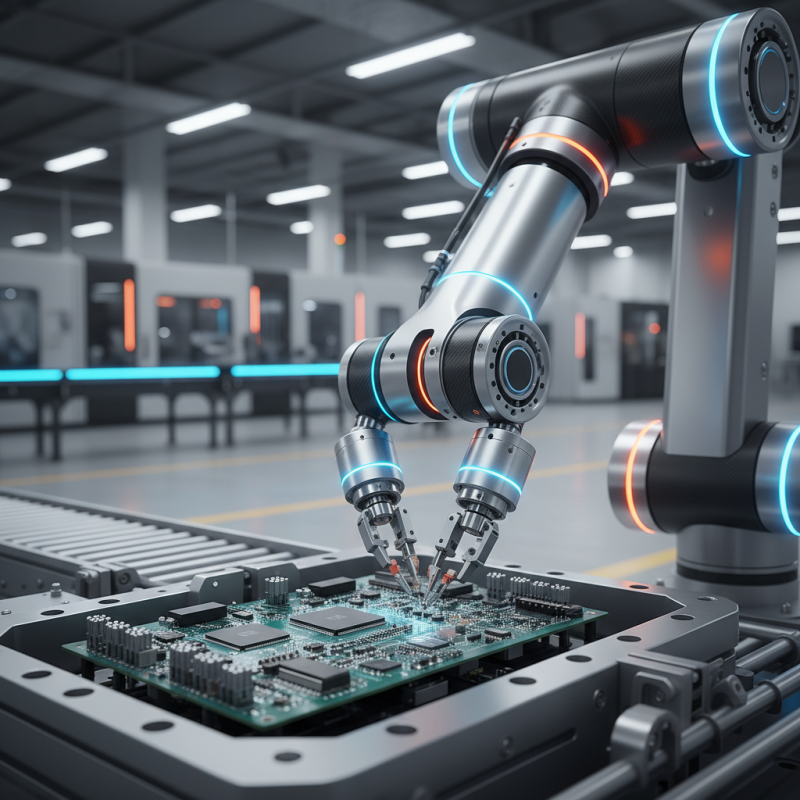

Robot joints are transforming automation projects across various industries. They offer precise movement, flexibility, and adaptability. This flexibility allows them to handle different tasks efficiently. With the rise of custom applications, robot joints provide tailored solutions that traditional machinery cannot. This adaptability is vital for responding to changing production needs.

Moreover, using robot joints enhances scalability. Businesses can start small and expand as needed. However, integrating these systems can be complex. They require proper programming and calibration. Not all teams may have the expertise to handle these challenges. Training is essential to maximize the benefits of robot joints. Without proper knowledge, the initial investment might not yield the best results.

Additionally, robot joints contribute to safety in the workplace. They can take over dangerous tasks, reducing risks for human workers. But, it’s crucial to address potential issues. Misalignment can lead to accidents. Continuous monitoring is needed to ensure optimal performance. Investing in robot joints means committing to ongoing learning and adaptation. Organizations must be willing to reflect and refine their processes for success.

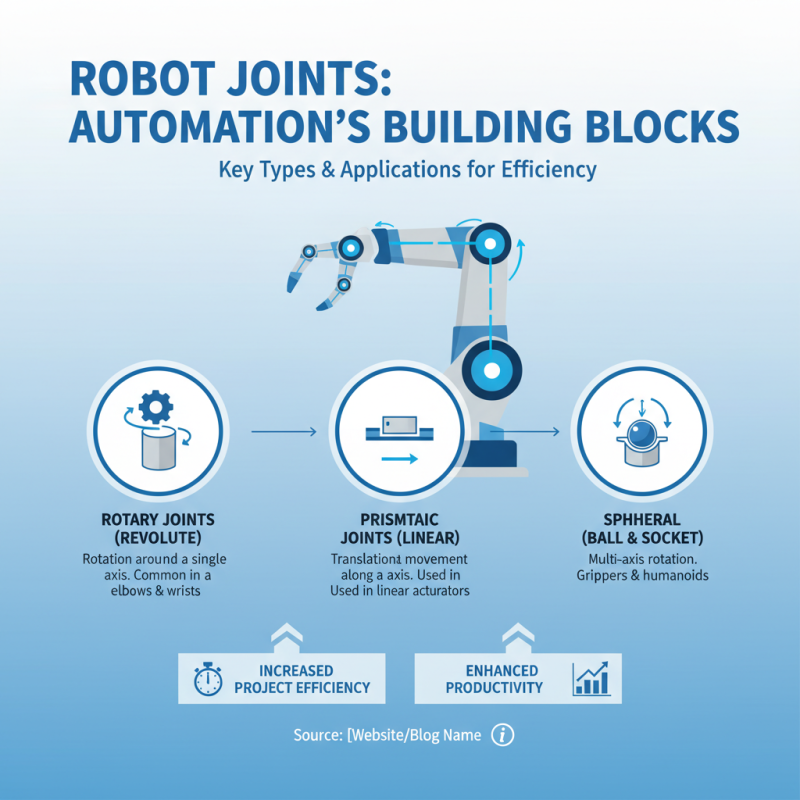

Types of Robot Joints and Their Applications

Robot joints play a pivotal role in automation projects. Different types serve various applications in industries. Understanding these joints can elevate project efficiency and productivity.

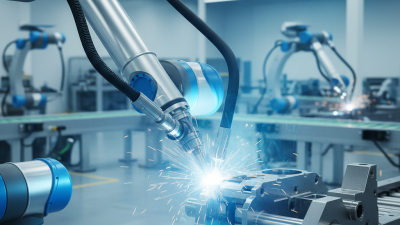

Articulated joints are versatile. They resemble a human arm and can perform complex tasks with precision. Industries often use them for assembly, welding, and painting. A market report by ResearchAndMarkets indicates that articulated robots dominate over 40% of the robotics market due to their adaptability.

Another type, SCARA joints, excel in high-speed operations. These joints are commonly found in assembly lines, particularly in electronics manufacturing. Their speed is a key advantage, with some models achieving 2,000 cycles per hour. This efficiency can dramatically boost production rates.

**Tips:** When selecting robot joints, assess project needs carefully. Consider the workspace and the types of tasks involved. Always analyze the total cost of ownership, not just the upfront costs. Also, be ready to adapt your design as new technology emerges.

There's a potential downside. Not all joints will suit every task. For example, while articulated joints are flexible, they might be overkill for simple tasks. This could lead to unnecessary costs. It’s vital to strike the right balance between capability and simplicity in your automation project.

Factors to Consider When Choosing Robot Joints

When selecting robot joints for automation projects, several key factors must be assessed.

First, the application type dictates the joint's requirements. For instance, high-speed operations need lightweight, agile joints, while

heavy load tasks demand robust and durable designs. According to a recent industry report, over

45% of automation projects fail due to inadequate joint selection.

This highlights the significance of matching the joint characteristics with project needs.

Compatibility with existing systems is another crucial consideration. Many projects require integration with various automation components.

Incompatibility can lead to increased costs and delays. A survey found that 35% of automation projects experience setbacks related to component

integration issues. These challenges serve as a reminder that meticulous alignment among robotics elements is vital.

Sensitivity to operational environments is also essential. Some joints perform poorly in extreme temperatures or dusty conditions.

It’s vital to evaluate conditions before final decision-making. Interestingly, about 20% of users discovered their joints malfunctioned due to

environmental oversight. This indicates a critical gap in planning that can lead to future re-evaluation and adjustments.

Technological Advances in Robot Joint Design

Technological advances in robot joint design have transformed automation. These innovations enhance flexibility and precision. The latest studies indicate that smart joints can improve productivity by up to 30%. This data reflects the growing importance of efficiency in manufacturing.

Traditional joints often lack adaptability. With new designs, robots can now perform complex tasks. For example, sensors in joints enable real-time adjustments. This capability can lead to better performance, but it adds complexity. Engineers must consider maintenance needs and the potential for increased wear.

The integration of AI in joint technology introduces exciting possibilities. AI-driven joints can learn from their environment. However, these advancements may complicate programming and require skilled technicians. As the industry evolves, companies need to balance high-tech solutions with user-friendly operation.

Why Choose Robot Joints for Your Next Automation Project?

| Dimension | Description | Benefits | Applications |

|---|---|---|---|

| Degrees of Freedom | The number of independent movements a joint can perform. | Enhanced flexibility and adaptability in automation tasks. | Robotic arms, collaborative robots. |

| Weight Capacity | The maximum load a robot joint can lift or support. | Improved efficiency in handling heavy loads. | Industrial robots, automation in logistics. |

| Speed | Rate at which the joint can move. | Faster production cycles and reduced downtime. | Manufacturing, assembly lines. |

| Material | Types of materials used for joint construction. | Durability and resistance to wear in harsh conditions. | Automotive, aerospace applications. |

| Cost Efficiency | The overall cost of installation and maintenance. | Lower operational costs and higher ROI. | Production automation, packaging. |

Case Studies: Successful Automation Projects with Robot Joints

In recent years, several automation projects have significantly benefited from the integration of robot joints. One notable case involved an automotive assembly line. By replacing conventional pneumatic systems with robot joints, the assembly speed increased by 30%. Workers reported easier handling of components, reducing strain injuries. The joints provided flexibility and reach that traditional systems lacked. However, initial setup complexities did introduce delays.

Another successful instance occurred in the food packaging sector. A facility used robot joints to streamline the sorting and packing process. They achieved a consistent output of 1,000 packages per hour. The adaptability of the robot joints allowed for quick changes in packaging designs. Yet, the learning curve for staff was steep. Some operators initially struggled with the technology, illustrating that training is crucial.

The application of robot joints has transformed many production lines. However, these systems sometimes require recalibration for accuracy. This necessity can disrupt workflow, suggesting that a balance between innovation and operational continuity is essential. Despite these challenges, the real-world impacts are promising.

Related Posts

-

Top Industrial Robot Types You Should Know About?

-

2025 Guide: How to Optimize Robotic Arc Welding for Maximum Efficiency

-

How to Choose the Right Inspection Robot for Your Industry Needs

-

Exploring the Future of Robotic Process Automation for Business Efficiency

-

Why Robotic Welding Systems Are Revolutionizing the Manufacturing Industry Today

-

Why Use Robot Software for Your Business Success?