Top 2025 Welding Robots: Innovations Transforming the Industry

As the manufacturing landscape evolves, the welding robot industry is witnessing a remarkable transformation driven by cutting-edge innovations. Leading experts in the field, such as Dr. Emily Larson, a renowned robotics engineer, emphasize the significant impact of these advancements. "The future of welding lies in automation and robotics, where precision and efficiency are taken to unprecedented levels," she states. This encapsulates the ongoing revolution within the realm of welding robots, where technology meets the art of fabrication.

The year 2025 promises to be a turning point for welding robots, as new technologies enhance their capabilities, making them indispensable in various industries. From improved artificial intelligence algorithms to sophisticated sensory systems, these innovations are not just reshaping how welding tasks are performed, but also redefining the roles of human workers alongside these advanced machines. As Dr. Larson highlights, the integration of welding robots into production lines is not merely about replacing human labor; it is about augmenting it, thereby encouraging a collaborative future where humans and robots work harmoniously.

In this dynamic environment, the welding robot sector is set to flourish, paving the way for increased productivity and quality. With a clear vision for the future, industry stakeholders must stay abreast of these transformative trends, ensuring they harness the full potential of welding robotics to drive business success and sustain competitive advantage in an ever-evolving market.

Key Features of the Latest Welding Robots in 2025

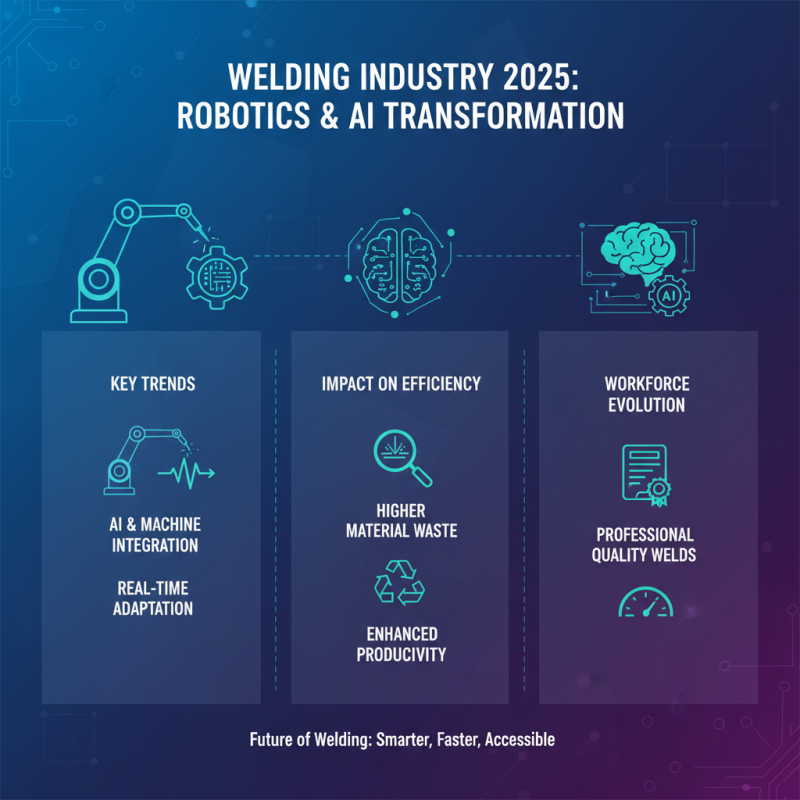

In 2025, the welding industry is witnessing remarkable innovations in robotics, significantly enhancing productivity, precision, and versatility. The latest welding robots boast advanced features such as artificial intelligence integration, which allows for real-time adjustments based on feedback from the welding process. This capability ensures optimal weld quality and reduces material waste, addressing common challenges faced in traditional welding methods. Additionally, the use of machine learning algorithms enables these robots to improve over time, adapting to different welding environments and requirements with ease.

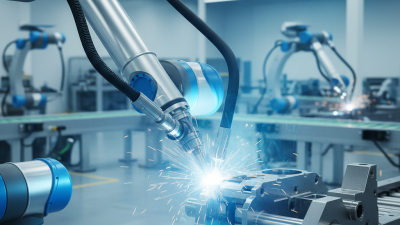

Collaboration is also a key theme in the latest welding robots. With the introduction of collaborative robots (cobots), workers and machines can operate side by side, combining human skill with robotic efficiency. This synergy not only enhances safety but also streamlines workflows, allowing for greater flexibility in production lines. Coupled with user-friendly interfaces, these robots enable operators to program and monitor tasks effortlessly, making the technology accessible even to those with limited experience in robotics.

**Tips:** When considering upgrading welding equipment, assess the specific needs of your production environment. Ensure that the features of the new robots align with your workflow requirements. Additionally, training your team to work effectively with these advanced systems will maximize their potential and lead to increased operational efficiency. Staying abreast of industry trends will also help you leverage the latest technologies effectively.

Innovative Technologies Driving Welding Robot Development

Innovative technologies are playing a pivotal role in the development of welding robots, driving significant advancements in efficiency, precision, and adaptability. One of the most notable innovations is the integration of artificial intelligence and machine learning algorithms. These technologies enable welding robots to analyze data in real-time, allowing them to optimize welding parameters automatically and improve quality control. With enhanced sensors, these robots can detect anomalies during the welding process, adjusting their operations instantly to maintain precision and consistency.

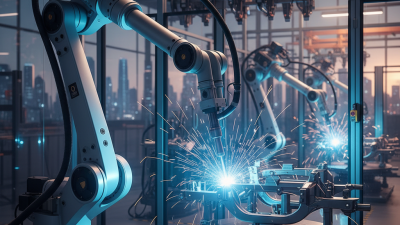

Another transformative development is the incorporation of collaborative robots, or cobots, which enhance human-robot interactions in welding applications. These robots are designed to work alongside human operators, providing assistance while ensuring safety and increasing productivity. Their advanced safety features allow for close proximity operations without the need for extensive guarding, making them ideal for tasks that require both human ingenuity and robotic efficiency. Additionally, developments in welding technologies such as laser and arc welding are being seamlessly integrated into robotic systems, expanding their capabilities and application fields across various industries.

Together, these innovations are not only improving the technical aspects of welding robots but also revolutionizing workflows in manufacturing, enabling companies to meet the growing demand for high-quality, precision welding with greater speed and flexibility.

Top 2025 Welding Robots: Innovations Transforming the Industry

| Robot Model | Payload Capacity (kg) | Welding Speed (m/min) | Precision (mm) | Power Consumption (kW) | Innovative Features |

|---|---|---|---|---|---|

| Model A | 150 | 18 | 0.05 | 2.0 | AI Integration, Adaptive Learning |

| Model B | 200 | 20 | 0.03 | 2.5 | Smart Sensors, Remote Monitoring |

| Model C | 120 | 25 | 0.04 | 1.8 | 3D Vision, Enhanced Safety Features |

| Model D | 250 | 22 | 0.02 | 3.0 | Multi-tasking, Real-time Data Analysis |

| Model E | 180 | 19 | 0.06 | 2.2 | User-friendly Interface, High Mobility |

Impact of Automation on the Welding Industry Landscape

The welding industry is undergoing a dramatic transformation as automation becomes increasingly prevalent. According to a recent report by the International Federation of Robotics (IFR), the global market for industrial robots, including welding robots, is projected to grow at a compound annual growth rate (CAGR) of 15% by 2025. This rapid growth is driven by advancements in robotics technology, enabling manufacturers to enhance efficiency, precision, and safety in their welding processes.

Automation in welding not only improves productivity but also significantly reduces labor costs. A study by the American Welding Society (AWS) highlighted that companies adopting robotic welding systems can achieve up to a 30% reduction in operational costs. Moreover, automation allows for a more consistent quality of work, minimizing defects and the need for rework. As industries invest in smart welding solutions, the integration of artificial intelligence (AI) and machine learning into welding robots further optimizes operations, enabling real-time adjustments based on varying materials and environmental conditions.

The transition to automated welding processes is reshaping workforce dynamics as well. While there is a looming concern about workforce displacement, studies indicate that robotics will complement skilled labor rather than replace it, with a projected demand for skilled technicians to oversee robotic systems. The welding industry is evolving to meet the challenges of the future, where collaboration between humans and robots will define productivity and innovation trajectories.

Applications of Advanced Welding Robots Across Various Sectors

Advanced welding robots are revolutionizing various sectors by enhancing precision, efficiency, and consistency in manufacturing processes. In the automotive industry, these robots are applied in the assembly of complex structures, ensuring high-quality welds that contribute to vehicle safety and durability. With real-time monitoring and adaptive capabilities, they can perform intricate welding tasks that would be challenging for human workers, significantly speeding up production times and reducing the margin for error.

In the aerospace sector, advanced welding robots are utilized for the fabrication of lightweight components, essential for improving fuel efficiency and performance. These robots can execute specialized welding techniques such as laser welding, which allows for minimal heat input and reduced warping of materials. Additionally, in the construction industry, robotic welding systems are being employed to automate tasks such as steel frame assembly and bridge construction. This not only accelerates project timelines but also enhances worker safety by taking over hazardous welding operations, showcasing the transformative impact of advanced welding technologies across multiple industries.

Top 2025 Welding Robots: Innovations Transforming the Industry

This chart illustrates the increasing applications of advanced welding robots across various sectors by the year 2025. The sectors highlighted include Automotive, Aerospace, Construction, and Electronics, showcasing the predicted growth in the adoption of welding robots.

Future Trends in Welding Robotics and Industry Growth

The welding industry is on the brink of a significant transformation driven by advancements in robotics technology. As we look toward 2025, several key trends are emerging that are poised to reshape not only the landscape of welding but also its operational efficiencies and capabilities. One of the most notable trends is the integration of artificial intelligence (AI) and machine learning algorithms into welding robots. These innovations enable machines to learn from their environments and adjust their parameters in real-time, resulting in higher precision and reduced material waste. This shift not only enhances productivity but also reduces the skill gap in the workforce, allowing less experienced operators to achieve professional-quality results.

Moreover, the growing emphasis on automation is facilitating the adoption of collaborative robots, or cobots, in welding applications. Unlike traditional welding robots that operate independently, cobots are designed to work alongside human operators safely. This collaboration can help enhance workflow efficiency and boost overall productivity, as these robots can take over the more monotonous aspects of welding tasks, freeing skilled workers to focus on complex operations that require human intuition. With the continuous innovations in user-friendly interfaces, even small manufacturers can easily incorporate advanced robotic systems, opening up the industry to new players and fostering healthy competition. This democratization of technology is a clear indicator of the growth potential in the welding sector as it adapts to increasing demands for efficiency and quality in manufacturing processes.

Related Posts

-

Revolutionizing Metal Fabrication with Seam Tracking Welding Technology for Precision Parts Production

-

Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry

-

Exploring the Future of Robotic Laser Welding in Advanced Manufacturing Techniques

-

2025 How to Enhance Robotic Performance with 3D Vision Systems in Automation

-

How to Master Robotic Arc Welding: Tips, Techniques, and Best Practices

-

2025 Guide: How to Optimize Robotic Arc Welding for Maximum Efficiency