Why Is Seam Tracking Welding Essential for Precision in Modern Manufacturing?

Seam tracking welding has emerged as a critical technology in modern manufacturing, ensuring precision and efficiency in various industrial applications. According to industry reports by the International Institute of Welding, the integration of advanced seam tracking systems in welding operations can improve weld quality by over 30% while significantly reducing material waste. As manufacturing processes continue to evolve, the demand for high precision in welds has led to the widespread adoption of seam tracking solutions that can adapt to complex geometries and variable production conditions.

Experts in the field, such as Dr. Emily Reynolds, a renowned welding technology specialist, emphasize the importance of this innovation, stating, "Seam tracking welding is not just an enhancement but a necessity for achieving optimal precision in today’s competitive manufacturing landscape." As industries increasingly focus on automation and smart manufacturing practices, the role of seam tracking technology becomes even more paramount. By enabling real-time adjustments during the welding process, manufacturers can not only enhance product quality but also boost overall productivity, ensuring they remain competitive in a rapidly changing market.

Understanding Seam Tracking Welding Technology and Its Mechanisms

Seam tracking welding technology plays a vital role in enhancing precision in modern manufacturing. This innovative approach utilizes advanced sensors and algorithms to continuously monitor and adjust the welding process in real-time. By precisely identifying the location of a weld seam, this technology ensures that the welding torch remains perfectly aligned throughout the operation, resulting in higher-quality welds with improved consistency and reduced defects. The integration of seam tracking systems enables manufacturers to achieve tighter tolerances and enhance overall productivity.

The mechanisms behind seam tracking welding are rooted in various sensor technologies, including laser, ultrasonic, and vision-based systems. These sensors gather critical data about the geometry and position of the workpiece, allowing for immediate adjustments during the welding process. The integration of machine learning algorithms further enhances this technology by enabling predictive adjustments based on real-time feedback. As a result, manufacturers can optimize their welding operations, reduce rework, and minimize material wastage. This level of technology not only boosts efficiency but also aligns with the increasing demand for high-quality, precision-engineered products in today’s competitive market.

Why Is Seam Tracking Welding Essential for Precision in Modern Manufacturing?

| Dimension | Data |

|---|---|

| Accuracy Rate | ±0.01 mm |

| Speed of Welding | 15 m/min |

| Material Types Supported | Steel, Aluminum, Stainless Steel |

| Adaptability | Automatic adjustment for varying seams |

| Reduction in Waste | Up to 30% |

| User Training Required | Minimal; system is user-friendly |

| Market Growth Rate | 10% annually |

The Role of Seam Tracking in Enhancing Welding Precision and Quality

Seam tracking welding has emerged as a crucial technology in modern manufacturing, particularly due to its significant impact on welding precision and quality. According to industry reports, seamless production processes can enhance overall efficiency by reducing errors by as much as 30%. This precision not only ensures that the welds are consistent but also minimizes the need for costly rework, which can account for up to 20% of total production costs. Advanced seam tracking systems provide real-time feedback, allowing welders to adjust their techniques dynamically, thus enhancing quality while maintaining the integrity of materials.

To maximize the benefits of seam tracking, manufacturers should invest in continuous training for their operators. Understanding how to effectively utilize seam tracking technology can drastically improve weld quality and operational output. Additionally, regular calibration and maintenance of tracking systems are essential to maintain their accuracy and reliability.

Furthermore, implementing seam tracking can contribute to reduced material waste. Inefficient welding processes often lead to excess scrap, with studies indicating that improving welding precision can decrease waste by up to 15%. By fostering a culture of quality and precision through seam tracking, manufacturers can not only enhance their product offerings but also achieve sustainability goals.

Applications of Seam Tracking Welding in Various Industries

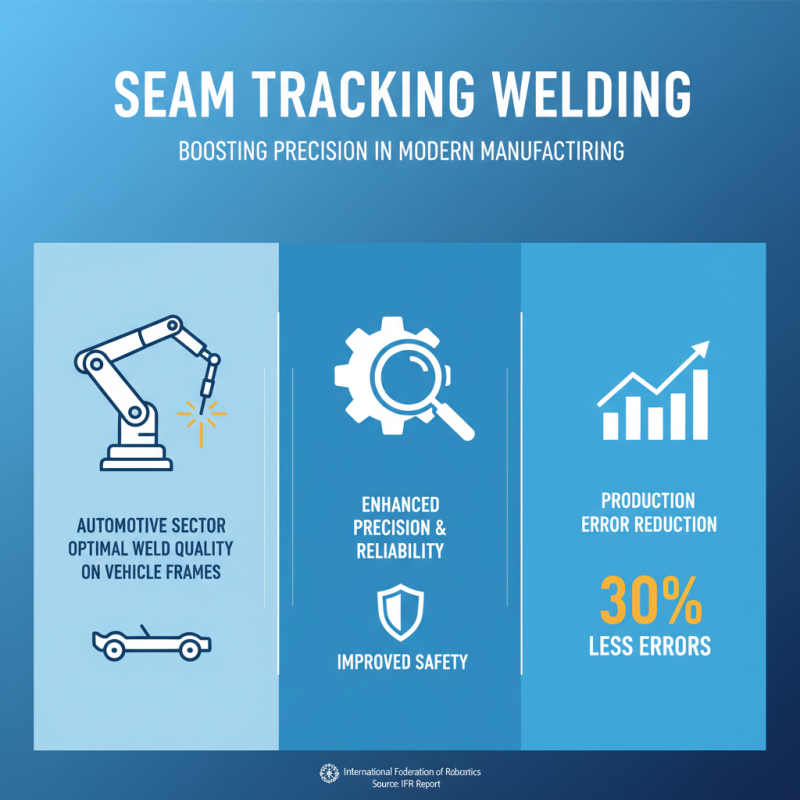

Seam tracking welding has emerged as a vital technology in modern manufacturing, significantly enhancing precision across a variety of industries. One of its most noteworthy applications is in the automotive sector, where manufacturers are increasingly relying on seam tracking systems to ensure optimal weld quality on vehicle frames. A report by the International Federation of Robotics indicates that automation, including seam tracking, can reduce production errors by up to 30%, resulting in both cost savings and improved safety for end users.

In addition to automotive manufacturing, seam tracking welding is being adopted in aerospace and shipbuilding industries. These sectors require impeccable weld integrity due to stringent safety regulations. According to a study from the American Welding Society, using advanced welding techniques such as seam tracking can improve the speed of high-precision welds by up to 25%, thereby minimizing downtime and increasing overall productivity.

**Tip:** When implementing seam tracking technology, it’s essential to conduct thorough training for operators to ensure they maximize the capabilities of the system. Proper calibration and routine maintenance can further enhance accuracy and prolong equipment lifespan.

Moreover, the energy sector is also beginning to embrace this technology for assembling pipelines and structural components. The use of seam tracking in these applications has been found to enhance the alignment of complex joints significantly. A data report from the Manufacturing Institute estimates that innovations in welding technology can result in a 10% reduction in material waste, underscoring the environmental benefits of precise welding practices.

**Tip:** Consider engaging in collaborative efforts with technology providers for customized seam tracking solutions that cater specifically to your manufacturing needs. Tailoring the approach can often lead to more effective results, particularly in specialized applications.

Comparison of Seam Tracking Welding with Traditional Welding Techniques

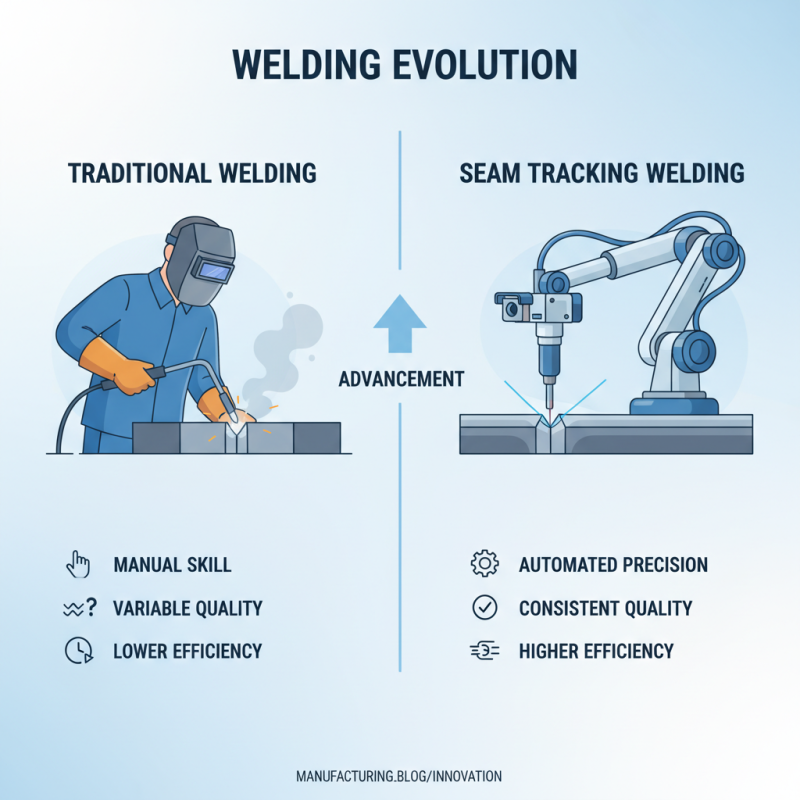

Seam tracking welding has emerged as a revolutionary advancement in modern manufacturing, particularly when juxtaposed with traditional welding techniques. Traditional welding often relies on the welder's skill to align and maintain a consistent seam, which can lead to variability in quality and precision. In contrast, seam tracking welding employs advanced technologies such as sensors and computer systems that actively monitor and adjust the welding process in real-time. This automation not only minimizes errors but also enhances the overall efficiency of the manufacturing process.

One notable advantage of seam tracking over traditional methods is its ability to adapt to variations in workpiece geometry. This flexibility is crucial when dealing with complex designs or materials that may shift during production. Furthermore, seam tracking systems can work at higher speeds without sacrificing quality, producing clean, uniform welds that meet stringent industry standards. As a result, manufacturers can achieve greater consistency in their outputs, ultimately leading to reduced rework and waste.

**Tips:** When considering the implementation of seam tracking welding, assess your production requirements thoroughly. Invest in training for your team to understand the technology fully, ensuring that they can maximize its capabilities. Additionally, routinely evaluate the system's performance to maintain high standards of efficiency and quality.

Future Trends and Innovations in Seam Tracking Welding Technology

The evolution of seam tracking welding technology is paving the way for unprecedented precision in modern manufacturing. As industries increasingly turn to automation and robotics, the integration of advanced seam tracking systems enhances the accuracy of weld placement, ensuring consistency and reducing material waste. Innovations such as real-time monitoring and adaptive algorithms allow welding machines to adjust to variations in the workpiece geometry and environmental conditions, which is crucial for achieving optimal weld quality in complex assemblies.

Looking ahead, the future of seam tracking welding lies in the development of intelligent systems that utilize machine learning and artificial intelligence. These technologies will enable welding equipment to learn from previous tasks, improving their efficiency over time and reducing the need for constant human oversight. Moreover, innovations such as enhanced sensor technologies and 3D vision will provide even greater feedback and control during the welding process. As these advancements continue to unfold, we can expect seam tracking welding to play an increasingly vital role in meeting the precision demands of next-generation manufacturing.

Seam Tracking Welding Efficiency Comparison (2023)

This bar chart illustrates the welding efficiency of different seam tracking welding technologies in 2023. As we can see, advanced seam tracking and AI-enhanced tracking technologies significantly improve welding efficiency compared to traditional methods, highlighting the importance of innovation in modern manufacturing processes.

Related Posts

-

Why Robotic Welding Systems Are Revolutionizing the Manufacturing Industry Today

-

How to Leverage Robotic Vision for Enhanced Automation in 2025

-

Revolutionizing Manufacturing: The Impact of Laser Robots on Precision Engineering

-

Top Robotic Vision Technologies Transforming Industries Today

-

Top 10 Amazing Innovations in Robot Vision Technology You Need to Know

-

Exploring the Future of Robot Servos at the 138th China Import and Export Fair in 2025