Top Robotic Vision Technologies Transforming Industries Today

The rapid advancement of technology has paved the way for groundbreaking innovations across various industries, with robotic vision emerging as a transformative force. Robotic vision, the field that encompasses the automated interpretation of visual data by machines, is revolutionizing how industries operate. From manufacturing and logistics to healthcare and agriculture, the ability of robots to "see" and analyze their surroundings is enhancing operational efficiency, improving quality control, and enabling automation that was previously unimaginable.

As organizations strive to stay competitive in an ever-evolving market, the adoption of robotic vision technologies is crucial. These systems harness sophisticated algorithms and advanced sensors, allowing robots to perform tasks with high precision and reliability. Whether it’s assessing product quality on an assembly line or identifying anomalies in medical imaging, robotic vision facilitates real-time decision-making that significantly boosts productivity. By diving into the latest advancements and applications of robotic vision, we can better understand its impact on various sectors and the future it promises for the labor market and global economy.

Innovations in Robotic Vision: A Brief Overview

Robotic vision technologies are evolving rapidly, fundamentally transforming various industries by enhancing automation and efficiency. Innovations such as advanced imaging sensors and deep learning algorithms are instrumental in enabling robots to interpret and respond to visual data accurately. For instance, according to a report by MarketsandMarkets, the robotic vision market is projected to reach $3.5 billion by 2026, growing at a compound annual growth rate (CAGR) of 12.4% from 2021. This growth is largely driven by the increasing demand for automation in manufacturing, logistics, and inspection processes.

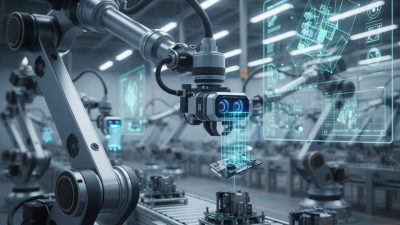

In the field of manufacturing, robotic vision systems are crucial for quality control and precision tasks. These systems utilize high-resolution cameras and sophisticated software to conduct real-time inspections, significantly reducing error rates and production downtime. A study by Deloitte indicated that organizations implementing robotic vision solutions could improve operational efficiency by up to 30%. In addition, these technologies are also making significant strides in healthcare, where they assist in surgical procedures and diagnostics, showcasing their versatility and importance across sectors.

Key Technologies Driving Robotic Vision Forward

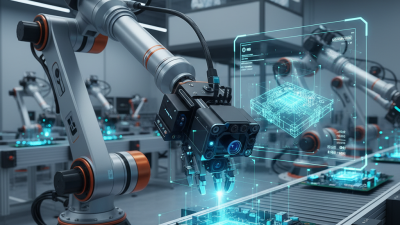

Robotic vision technologies are at the forefront of industrial innovation, significantly enhancing efficiency and accuracy across various sectors. Central to this transformation are advances in machine learning and artificial intelligence, enabling robots to interpret complex visual data. This capability allows systems to identify and classify objects with remarkable precision, which is crucial for applications in manufacturing, logistics, and quality control. By leveraging deep learning algorithms, these technologies can continuously improve their performance, adapting to new tasks and environments over time.

Another key driver of robotic vision forward is the integration of advanced sensors and cameras. High-resolution imaging, 3D vision systems, and LiDAR are revolutionizing how robots perceive their surroundings, providing them with richer, more detailed information. This enhanced perception enables robots to execute intricate tasks such as autonomous navigation and precision assembly with unprecedented reliability. As industries increasingly adopt these cutting-edge vision technologies, they not only streamline operations but also pave the way for innovative applications that redefine productivity and safety in the workplace.

Applications of Robotic Vision Across Various Industries

Robotic vision technologies are revolutionizing a multitude of industries by enabling machines to interpret visual data and make informed decisions. In manufacturing, for instance, organizations are leveraging robotic vision systems equipped with advanced cameras and AI algorithms to enhance quality control processes. According to a report by MarketsandMarkets, the robotic vision market is projected to grow from USD 1.2 billion in 2021 to USD 4.5 billion by 2026, indicating a compound annual growth rate (CAGR) of 30.3%. This surge is primarily driven by the increasing demand for automation and the need for faster, more accurate inspection methods.

In the healthcare sector, robotic vision technologies play a crucial role in surgical procedures and diagnostics. Robots with vision capabilities can assist surgeons by providing real-time feedback on the surgical field, increasing precision in complex operations. A study published in the Journal of Medical Robotics Research highlights that the adoption of robotic vision in surgery can reduce errors by up to 50%. Additionally, the logistics industry is witnessing the implementation of robotic vision for inventory management and automated picking systems, significantly improving operational efficiencies.

**Tips for Implementing Robotic Vision**:

1. Start with a thorough assessment of current processes to identify specific inefficiencies that robotic vision could resolve.

2. Consider partnering with technology providers that offer modular solutions allowing for easy integration into existing systems.

3. Invest in training your workforce to ensure they are equipped to work alongside advanced robotic systems for optimal results.

Impact of Robotic Vision on Operational Efficiency

Robotic vision technologies are becoming pivotal in enhancing operational efficiency across various industries. By integrating advanced imaging systems and artificial intelligence, these technologies enable robots to perceive and interpret their surroundings with remarkable precision. According to a report by MarketsandMarkets, the global machine vision market is projected to reach USD 12.31 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.8% from 2020. This growth underscores the increasing reliance of manufacturing, logistics, and healthcare sectors on robotic vision systems to optimize processes.

In manufacturing, for instance, companies leveraging robotic vision for quality control and inspection have demonstrated significant improvements in productivity. Features such as real-time defect detection and automated sorting have reduced downtime by up to 30%, allowing manufacturers to ramp up production efficiency. Additionally, research from McKinsey suggests that automation in supply chain operations, bolstered by robotics with vision capabilities, could lead to cost savings of 20-25%. As industries continue to adopt these transformative technologies, the impact on operational efficiency is undeniable, driving businesses toward greater competitiveness and sustainability.

Impact of Robotic Vision on Operational Efficiency in Various Industries

Challenges and Future Trends in Robotic Vision Technology

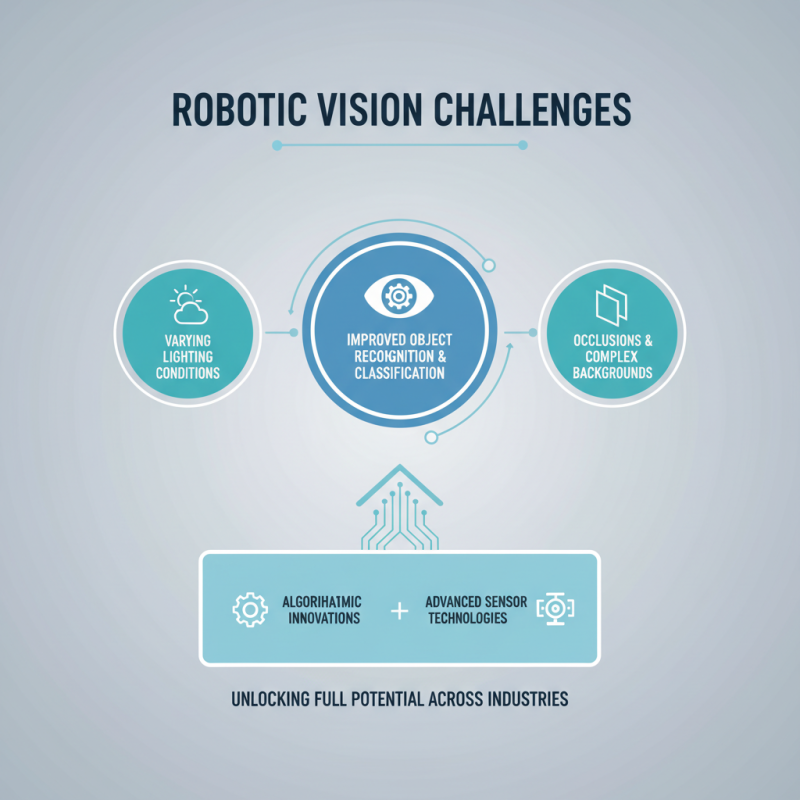

As robotic vision technology continues to evolve, it faces a myriad of challenges that must be addressed to unlock its full potential across various industries. One prominent challenge is the need for improved object recognition and classification capabilities. Despite advancements in machine learning and computer vision, robots still struggle with accurately identifying objects in dynamic environments. Factors such as varying lighting conditions, occlusions, and complex backgrounds can significantly hinder performance, necessitating further innovations in algorithms and sensor technologies.

Looking ahead, future trends in robotic vision technology suggest a shift towards greater integration with artificial intelligence and deep learning. These advancements promise to enhance the adaptability of robots, allowing them to learn from experiences and refine their vision systems over time. Additionally, the miniaturization of cameras and sensors will lead to more compact and versatile robotic solutions, facilitating widespread adoption across sectors such as manufacturing, healthcare, and logistics. As industries embrace these technologies, collaboration between researchers and practitioners will be crucial to overcoming the current obstacles and driving the next wave of innovation in robotic vision.

Related Posts

-

Exploring the Future of Robotic Vision: Innovations That Transform Industries

-

How to Choose the Best Robot Vision System for Your Business Needs

-

Top 10 Amazing Innovations in Robot Vision Technology You Need to Know

-

What is Robotic Vision? Understanding Its Importance and Applications in Automation

-

2025 How to Enhance Robotic Performance with 3D Vision Systems in Automation

-

How to Enhance Your Photography Skills with Innovative Camera Robots