Revolutionizing Industries: How Robot Vision Systems Enhance Automation and Efficiency

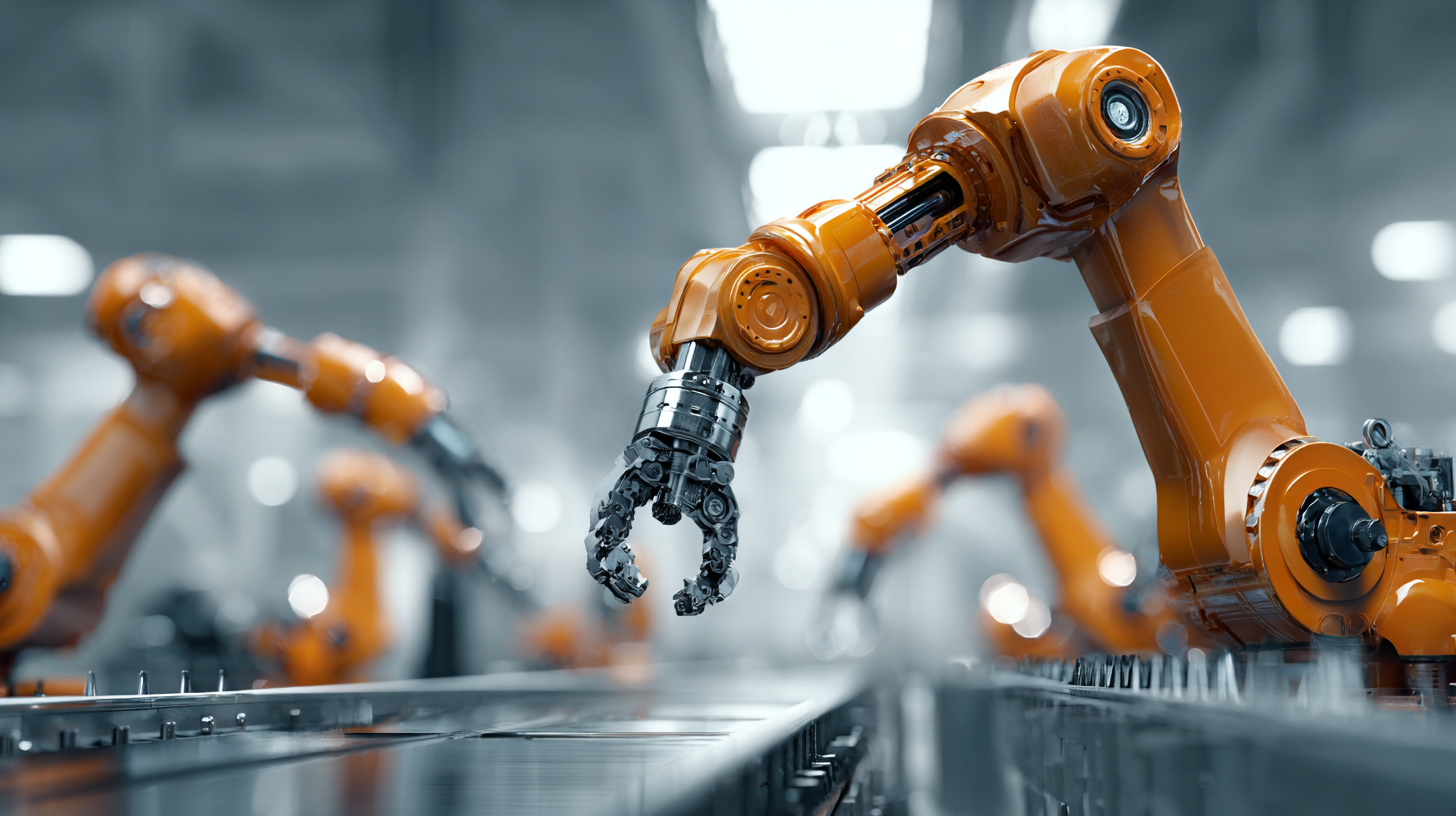

As industries strive for greater automation and efficiency, the adoption of advanced technologies has become imperative. One such transformative technology is the robot vision system, which enables machines to interpret and understand their environments with remarkable precision.

According to a report by MarketsandMarkets, the global market for robot vision systems is projected to reach $4.3 billion by 2025, growing at a CAGR of 13.4% from 2020 to 2025. This rapid expansion highlights the increasing reliance on visual data to drive automation processes in manufacturing, logistics, and other sectors.

The integration of robot vision systems not only enhances operational efficiency but also reduces errors and downtime, presenting significant cost savings. Companies that leverage this technology can achieve improved quality control, streamlined workflows, and ultimately, a competitive edge in a rapidly evolving marketplace.

The integration of robot vision systems not only enhances operational efficiency but also reduces errors and downtime, presenting significant cost savings. Companies that leverage this technology can achieve improved quality control, streamlined workflows, and ultimately, a competitive edge in a rapidly evolving marketplace.

Benefits of Integrating Robot Vision Systems in Manufacturing Processes

The integration of robot vision systems in manufacturing processes brings numerous benefits that significantly enhance automation and efficiency. By employing advanced imaging technologies and artificial intelligence, these systems enable robots to perceive their environment with remarkable accuracy. This capability allows robots to identify defects in products, ensuring higher quality control throughout the production line. As a result, manufacturers can reduce waste, minimize costs, and deliver superior products to customers.

Moreover, robot vision systems improve operational efficiency by enabling real-time feedback and adaptive decision-making. This technology allows robots to make instantaneous adjustments based on their visual assessments, leading to optimized workflow and reduced downtime. With the ability to perform complex tasks like sorting and assembly with precision, these systems empower manufacturers to increase output while maintaining safety standards. In an era where rapid production and adaptability are vital, the adoption of robot vision systems is transforming the capabilities of manufacturing environments.

Revolutionizing Industries: How Robot Vision Systems Enhance Automation and Efficiency

| Dimension | Description | Benefits | Impact (%) |

|---|---|---|---|

| Quality Control | Automated inspection of products for defects and quality assurance. | Increased accuracy and reduction of human error. | 95% |

| Speed of Production | Enhanced speed in processing and assembling products. | Reduction in production time and increased throughput. | 30% |

| Cost Efficiency | Lower production costs through minimized waste. | Greater profitability and reduced operational costs. | 25% |

| Flexibility | Adaptable systems that can change tasks easily. | Rapid response to changing market demands. | 40% |

| Safety | Reduction of workplace accidents by automating dangerous tasks. | Improvement of employee safety and reduced liability. | 60% |

Exploring the Role of AI in Enhancing Robot Vision Capabilities

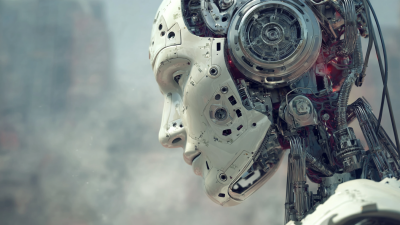

The integration of artificial intelligence (AI) into robot vision systems marks a significant advancement in automation technology. AI enhances the capabilities of these systems by enabling real-time data analysis and decision-making. Through machine learning algorithms, robots can learn to recognize and interpret complex visual information, such as identifying objects, determining distances, and even understanding contextual information. This evolution allows robots to adapt to various environments and perform tasks with a precision and flexibility that traditional automation methods often lack.

Moreover, improved robot vision capabilities facilitate increased efficiency in various industries, from manufacturing to logistics. AI-powered visual systems can quickly detect anomalies on production lines, reducing errors and minimizing downtime. In logistics, robots equipped with advanced vision can optimize warehouse operations by accurately locating and sorting items. By merging AI with robot vision, industries can not only streamline operations but also enhance safety and reduce operational costs, paving the way for a more intelligent and responsive automation landscape.

Challenges and Solutions in Implementing Robot Vision Technologies

Implementing robot vision technologies presents several challenges that industries must navigate to maximize automation and efficiency. One significant hurdle is the integration of these systems with existing machinery and workflows. According to a report by the International Federation of Robotics, nearly 65% of manufacturers cite compatibility issues with legacy systems as a barrier to adoption. Addressing this requires a tailored approach to retrofit existing machinery or develop adaptive robotic solutions that can seamlessly integrate into current operations.

Another challenge lies in the complexity of developing accurate vision algorithms capable of interpreting varied environments and tasks. Recent studies from the Boston Consulting Group indicate that about 60% of firms struggle with the training data necessary for machine learning in vision systems. Solutions to this include employing advanced simulation environments to generate synthetic data and enhance training processes. By leveraging these technologies, companies can improve the precision of their robotic vision systems, ultimately leading to a more efficient and flexible manufacturing process capable of responding swiftly to market demands.

Case Studies: Successful Applications of Robot Vision in Various Industries

The implementation of robot vision systems has transformed various industries by enhancing automation and operational efficiency. For instance, in the automotive sector, manufacturers have integrated sophisticated vision systems in their assembly lines. These systems utilize advanced imaging technology to inspect components in real-time, ensuring that only parts meeting quality standards proceed through the production process. This application not only reduces the likelihood of defects but also speeds up the quality assurance stage, significantly decreasing manufacturing downtime.

In the food processing industry, companies have leveraged robot vision for sorting and packing products. Automated systems equipped with cameras and image recognition software can distinguish between ripe and unripe fruits, ensuring that only the best products are selected for sale. This technology not only boosts productivity by minimizing manual sorting labor but also enhances food safety and reduces waste. The success of robot vision applications in these case studies showcases their potential to revolutionize operational workflows across diverse sectors, driving efficiency and precision.

Revolutionizing Industries: Robot Vision Systems Efficiency

This chart illustrates the impact of robot vision systems on automation efficiency across various industries, showcasing the percentage improvements in efficiency before and after implementation.

Future Trends in Robot Vision Systems and Automation Enhancements

The future of robot vision systems and their enhancements in automation is poised for remarkable growth, with the market size of the global artificial intelligence sector projected to escalate from $35.65 billion in 2023 to an astounding $253.86 billion by 2030, reflecting a compound annual growth rate (CAGR) of 32.4%. This expansion highlights the increasing reliance on advanced technologies, such as humanoid robots, which are integrating AI with robotics. By 2024, the humanoid robotics market is expected to showcase significant insights, driven by applications across education, healthcare, and entertainment.

Moreover, the 3D time-of-flight (ToF) imaging sensor market is also experiencing a robust growth trajectory, with a projected CAGR of 21.21%. These sensors are critical in enhancing robot vision systems by providing precise depth perception, which is essential for effective interaction with environments and humans. As these technologies evolve, the potential for automation in various industries will only increase, leading to greater efficiencies and innovative applications across sectors. By 2032, the artificial intelligence robot market is forecasted to reach a value of $322.6 billion, indicating an ongoing trend towards smarter and more capable robotic systems.

Related Posts

-

Transforming Industry with Intelligent Robots at the 138th Canton Fair in 2025

-

Exploring the Future of Robot Servos at the 138th China Import and Export Fair in 2025

-

Exploring the Future of Robotic Process Automation for Business Efficiency

-

Exploring the Future of Robotic Vision: Innovations That Transform Industries

-

Unlocking the Future of Automation with Digital Robotic Process Techniques

-

Unlocking the Future of Automation with Revolutionary Robot Software