What is a Robot Servo and How Does it Work?

Robots are becoming integral parts of modern technology. They serve various purposes in industries, from manufacturing to healthcare. At the heart of many robotic systems is the robot servo. Understanding how a robot servo functions is crucial for anyone interested in robotics.

A robot servo is a type of motor that controls movement. It receives signals and adjusts its position accordingly. This mechanism allows robots to perform precise actions, like picking up objects or moving limbs smoothly. However, not all robot servos are created equal. Each type has unique capabilities and limitations.

Common challenges exist in servo applications. In some cases, the feedback loop can lead to errors. When programming a robot servo, these pitfalls must be addressed to ensure smooth operation. Reflecting on these issues will help in designing better robotic systems in the future. Exploring the intricacies of robot servos opens a door to innovation in robotics.

What is a Robot Servo?

A robot servo is a crucial component in robotic systems. It allows for precise control of movement and position. These servos are often utilized in various applications, from hobbyist robots to advanced industrial machinery. The global market for servo motors is expected to reach $12 billion by 2025, reflecting increasing integration in automation.

Robot servos operate based on feedback loops. They receive signals from a controller, adjusting their position based on desired outcomes. However, a common issue is how quickly they can respond to commands. Some servos lag, which can disrupt performance. According to industry standards, response times can vary widely. This inconsistency raises questions about reliability in critical applications.

Moreover, it’s essential to consider energy consumption. Some servos may consume excess power, affecting overall efficiency. Engineers often overlook the importance of selecting the right power source. This oversight can lead to suboptimal performance. Striking a balance between power and efficiency remains a challenge for many developers in the field.

What is a Robot Servo and How Does it Work?

| Parameter | Description | Value |

|---|---|---|

| Type | Standard servo motor | Dynamixel MX-28 |

| Torque Rating | Maximum torque produced | 2.5 Nm |

| Speed | Angular velocity | 60 RPM |

| Control Method | How the servo is controlled | PWM (Pulse Width Modulation) |

| Feedback Type | Type of feedback sensor | Rotary encoder |

| Power Supply | Operating voltage range | 11.1V - 12.6V |

| Weight | Total weight of the servo | 90 g |

| Application | Common uses in robotics | Robot arms, leg motions |

Types of Robot Servos and Their Applications

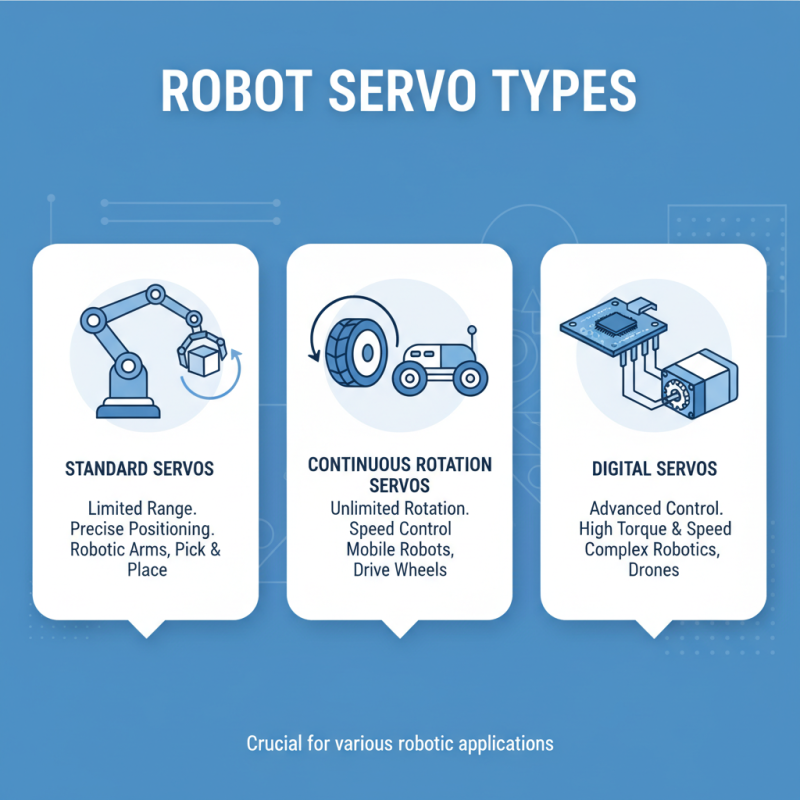

Robot servos play a crucial role in many applications. There are several types of robot servos, each serving different purposes. The most common types include standard servos, continuous rotation servos, and digital servos. Standard servos operate within a limited range and are ideal for precise positioning tasks. For example, they are widely used in robotic arms for tasks like pick-and-place operations.

Continuous rotation servos, on the other hand, can rotate indefinitely in either direction. This feature makes them suitable for driving wheels in mobile robots. According to a recent industry report, the demand for continuous rotation servos is rising, projected to grow by 10% annually. Digital servos provide enhanced control with faster response times. They can be found in applications requiring high precision, such as drones and advanced robotic systems.

While the benefits of using robot servos are clear, challenges exist in their implementation. The need for robust control algorithms can complicate their use. Furthermore, the integration of servos with different systems may require additional time and resources. There is also a risk of servo failure under heavy loads, which could lead to malfunctions. As the robotics field evolves, addressing these concerns becomes critical for achieving better performance across various applications.

How Robot Servos Function: The Mechanics Behind Movement

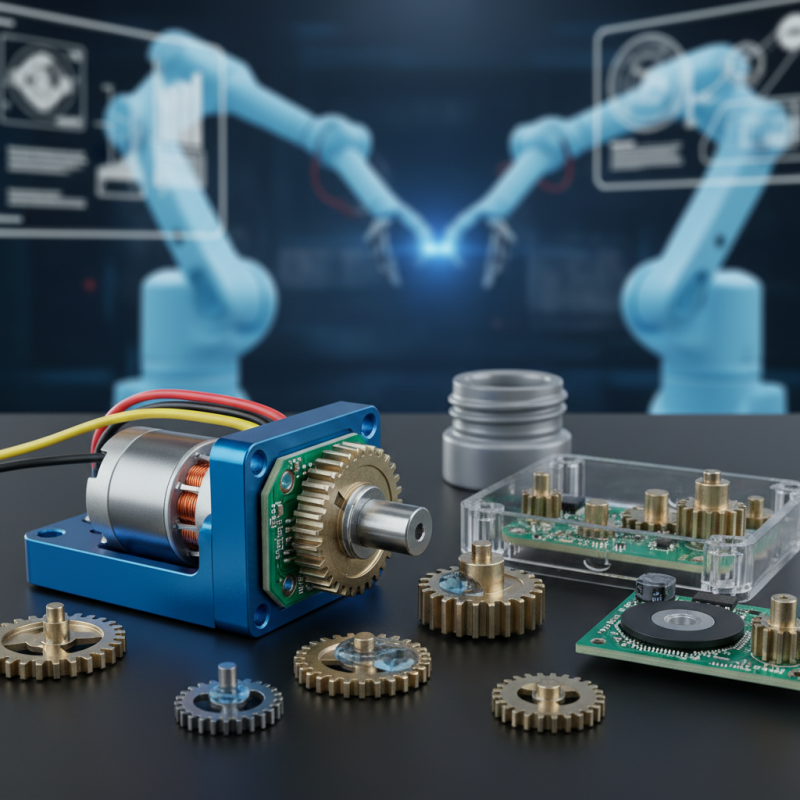

Robot servos are essential components in many automated systems. They enable precise control of motion, making them vital for robotics. Understanding their mechanics helps us appreciate how they function.

At the core of a servo is a motor. This motor moves based on signals it receives. Typically, these signals come from a microcontroller. The controller sends commands that dictate the position and speed of the servo. This is where feedback loops play a role. The servo sends back position information, ensuring accurate movements.

Tips: When working with servos, always check the power rating. Overloading them can cause failure. Calibration is also crucial. An uncalibrated servo might respond inaccurately.

In exploring servos, we might find challenges. For instance, noise can interfere with signal transmission. It’s important to minimize interference in circuits. Additionally, mechanical wear can affect performance. Regular maintenance can help prolong their lifespan and reliability.

Control Methods for Robot Servos: Analog vs. Digital Signals

Robot servos are essential in robotics, providing precise control of movement. The two main control methods for robot servos are analog and digital signals. Each method has unique characteristics and applications.

Analog signals are straightforward. They send continuous voltage levels that correspond to the desired position of the servo. However, they can be prone to noise, which affects accuracy.

In contrast, digital signals work with discrete values. They maintain a consistent quality over long distances and are less susceptible to interference. This robustness makes them ideal for complex systems.

Choosing between these methods can be a challenge. Analog systems might seem simpler, but they can lead to performance issues in noisy environments. On the other hand, digital systems require more sophisticated electronics and programming. Balancing simplicity and performance is crucial. Understanding the specific needs of the project helps in making the right choice.

Common Uses of Robot Servos in Robotics and Automation

Robot servos play a crucial role in robotics and automation. They provide precise control of movement, which is essential for many applications. One common use is in robotic arms. These arms often need to move smoothly and accurately. Servos enable this by adjusting angles and positions with great precision.

Another common application is in drones. Servos help control the pitch and yaw of the blades. This allows drones to maintain stability during flight. They are also essential for robotic vehicles, ensuring accurate steering and movement. These uses highlight the importance of servos in modern technology.

However, the integration of servos has challenges. Calibrating them can be tricky. Sometimes, the movement isn't as fluid as desired. Feedback loops need careful adjustment. Each application requires specific settings. Engineers often spend time testing and refining these mechanisms. As technology advances, finding improvements remains a key focus in robotics.

Related Posts

-

Exploring the Future of Robot Servo Technology at the 2025 China Import and Export Fair

-

Exploring the Future of Robot Servos at the 138th China Import and Export Fair in 2025

-

How to Choose the Best Robot Vision System for Your Business Needs

-

Revolutionizing Metal Fabrication with Seam Tracking Welding Technology for Precision Parts Production

-

Why Use Robot Software for Your Business Success?

-

2026 How to Get the Latest Robot News and Updates