Revolutionizing Metal Fabrication with Seam Tracking Welding Technology for Precision Parts Production

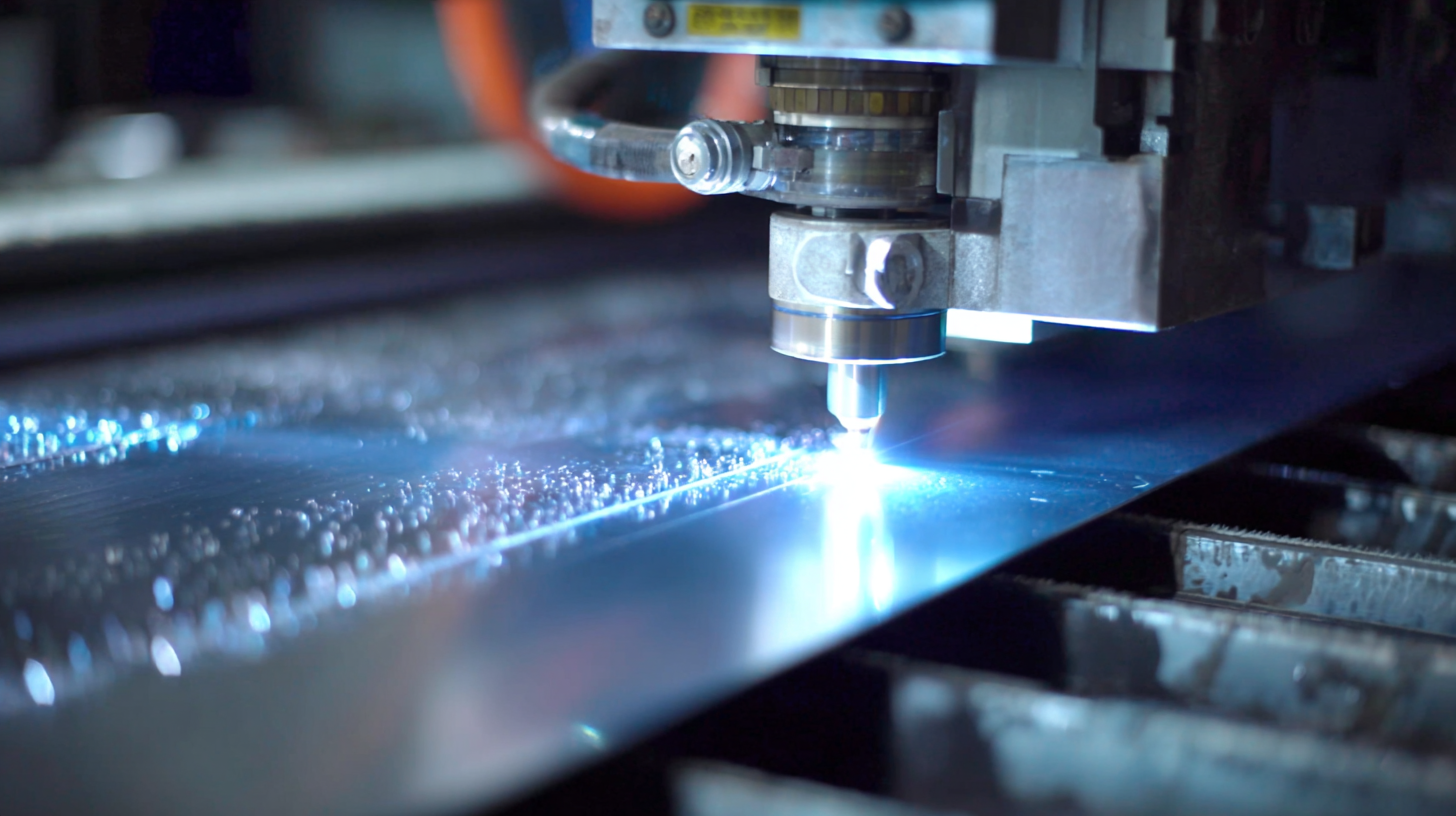

In the realm of metal fabrication, achieving precision in parts production has always been a pivotal goal for manufacturers seeking to enhance efficiency and reduce waste. Seam tracking welding technology emerges as a game-changer in this industry, offering unprecedented accuracy in joining metal components. By integrating advanced sensors and computer systems, seam tracking welding allows for real-time adjustments to the welding process, ensuring that the weld remains aligned with the parts being joined, even in the presence of irregularities. This innovative approach not only streamlines the fabrication process but also significantly improves the quality of the finished products. In this article, we will explore how to harness the power of seam tracking welding to revolutionize metal fabrication, boost productivity, and maintain the high standards required in precision parts production.

Harnessing Seam Tracking Technology for Enhanced Precision in Metal Fabrication

Seam tracking technology is transforming the landscape of metal fabrication, particularly in the production of precision parts. By utilizing advanced sensors and algorithms, this technology enables welding equipment to detect and follow seams in real-time, ensuring that each weld is perfectly aligned. This precision minimizes the risk of defects and enhances overall product quality, which is crucial in industries where tolerances are tight and performance is essential.

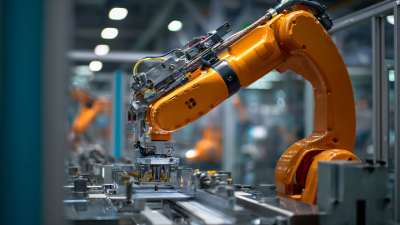

The integration of seam tracking technology into welding processes also streamlines production by reducing the need for manual adjustments and inspections. Automated systems can adapt to variations in material or joint configurations, which leads to faster turnaround times and increased efficiency. As manufacturers strive for more reliable and consistent outputs, harnessing this technology becomes a strategic advantage, allowing them to meet the demands of modern engineering and manufacturing challenges.

The Impact of Digital Innovations on Welding Process Efficiency and Accuracy

The advent of digital innovations in welding processes has significantly enhanced efficiency and accuracy, marking a pivotal shift in metal fabrication. Advanced technologies, such as digital twins, enable real-time monitoring and predictive maintenance in welding. This integration facilitates better decision-making, minimizes downtime, and optimizes resource management, thereby transforming traditional practices into more streamlined operations.

Moreover, the emphasis on precision in welding can be observed through the implementation of seam tracking welding technology. This technology ensures that welds are consistently accurate, thus improving the quality of production parts. As industries, especially aerospace, push towards sustainability and efficiency, the role of digital tools in achieving these goals becomes increasingly critical. The ongoing evolution of the welding power supply market also reflects this trend, with expectations of notable growth as companies invest in more intelligent and capable welding systems to meet rising demands for precision and reliability.

Real-Time Monitoring: Ensuring Quality Control in Seam Tracking Welding

Seam tracking welding technology represents a significant advancement in metal fabrication, providing real-time monitoring that ensures stringent quality control throughout the production process. This innovative approach utilizes sophisticated sensors and algorithms to detect the position of weld seams as they are formed. By continuously adjusting the welding parameters based on the actual seam alignment, manufacturers can achieve superior precision and consistency in the final product.

Real-time monitoring capabilities in seam tracking welding allow for immediate feedback on the welding quality, minimizing defects and reducing material waste. By identifying issues such as misalignment or variations in weld penetration, operators can make on-the-fly adjustments, ensuring that each component meets the exact specifications required for high-performance applications. This level of proactive quality assurance not only enhances the durability and functionality of precision parts but also promotes a more efficient production process, leading to significant cost savings for manufacturers.

Future Trends: Integrating AI and Machine Learning in Metal Fabrication

The integration of artificial intelligence (AI) and machine learning into metal fabrication is set to transform the industry, enhancing efficiency and precision in production processes. These advanced technologies can analyze vast amounts of data generated during fabrication, allowing for real-time adjustments and optimizations in welding techniques, such as seam tracking. This capability significantly reduces the margin for error, ensuring that each weld is executed with unparalleled accuracy, ultimately leading to higher quality precision parts.

Moreover, machine learning algorithms can predict potential issues during the fabrication process by identifying patterns and anomalies in operational data. This predictive maintenance not only minimizes downtime but also extends the lifespan of equipment. As manufacturers increasingly adopt these technologies, we can expect a shift toward a more automated and intelligent metal fabrication landscape, where the synergy of AI and seam tracking welding technology will pave the way for innovative production methods and enhanced competitiveness in the market.

Case Studies: Success Stories of Seam Tracking in High-Precision Industries

Seam tracking welding technology has emerged as a

game-changer in high-precision industries, where

accuracy and consistency are paramount. In the aerospace sector,

manufacturers have reported remarkable improvements in their fabrication processes after integrating

automated seam tracking systems. One notable case study involves a leading aerospace company that adopted

this technology, resulting in a 30% reduction in production time

and a significant improvement in weld quality. The ability to dynamically follow the joint contours during

welding minimized the risk of defects and rework, ultimately enhancing the overall efficiency of their operations.

Seam tracking welding technology has emerged as a

game-changer in high-precision industries, where

accuracy and consistency are paramount. In the aerospace sector,

manufacturers have reported remarkable improvements in their fabrication processes after integrating

automated seam tracking systems. One notable case study involves a leading aerospace company that adopted

this technology, resulting in a 30% reduction in production time

and a significant improvement in weld quality. The ability to dynamically follow the joint contours during

welding minimized the risk of defects and rework, ultimately enhancing the overall efficiency of their operations.

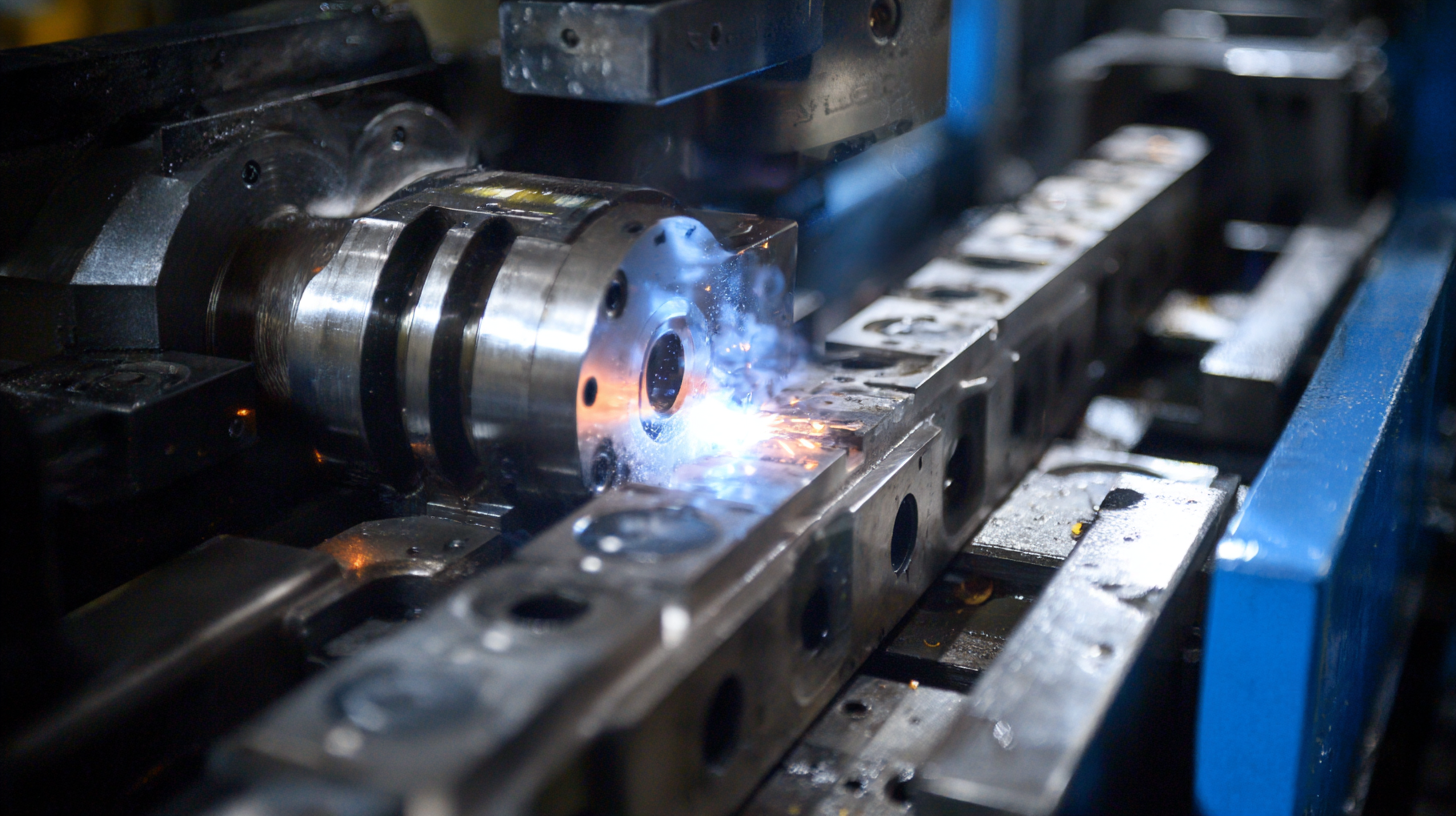

Another compelling example comes from the automotive industry, where precision parts production is critical for both performance and safety. A high-end automobile manufacturer implemented seam tracking technology in their assembly line for chassis components. This move not only increased production rates by 25% but also ensured that each weld met stringent regulatory standards. By utilizing real-time feedback from laser-based sensors to adjust the welding parameters on-the-fly, the company was able to produce components with exceptional fit and finish, leading to higher customer satisfaction and reduced warranty claims. These case studies exemplify the transformative impact of seam tracking welding technology across diverse high-precision manufacturing sectors.

Related Posts

-

How to Enhance Your Photography Skills with Innovative Camera Robots

-

Revolutionizing Manufacturing: The Impact of Laser Robots on Precision Engineering

-

Unlocking the Future of Automation with Digital Robotic Process Techniques

-

Exploring the Future of Robotic Process Automation for Business Efficiency

-

Exploring the Future of Manufacturing: How Servo Robot Seam Tracking Revolutionizes Precision Welding

-

Unlocking the Future of Automation with Advanced Robot Vision Systems