Revolutionizing Manufacturing: The Impact of Laser Robots on Precision Engineering

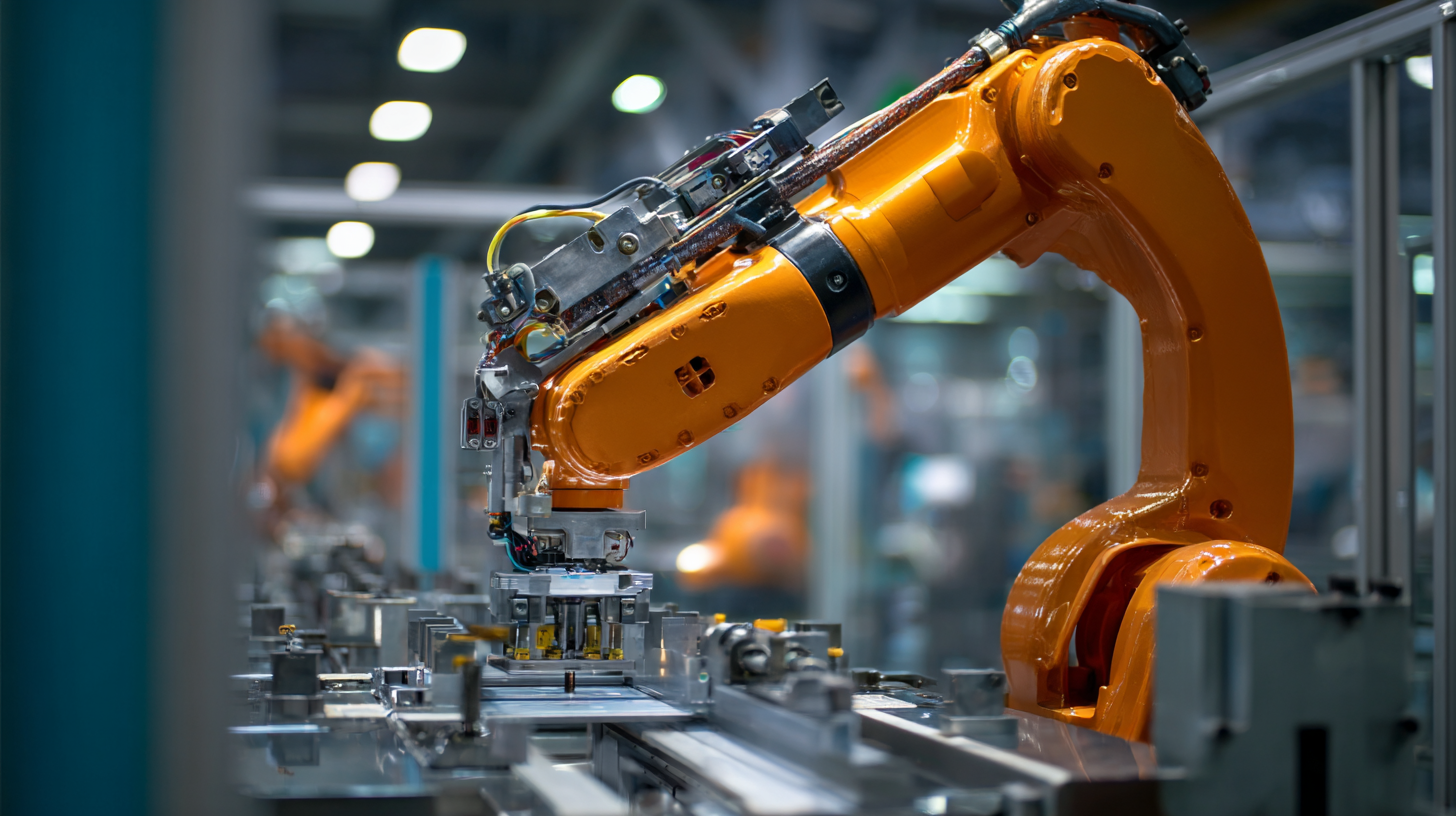

The advent of laser robots is heralding a new era in precision engineering, fundamentally transforming the landscape of manufacturing. With their unparalleled accuracy and efficiency, these advanced machines utilize laser technology to perform intricate cutting, welding, and surface treatment tasks that were once deemed impossible or too labor-intensive. By integrating laser robots into production processes, manufacturers can achieve a level of precision that enhances product quality and reduces waste, driving significant cost savings.

The advent of laser robots is heralding a new era in precision engineering, fundamentally transforming the landscape of manufacturing. With their unparalleled accuracy and efficiency, these advanced machines utilize laser technology to perform intricate cutting, welding, and surface treatment tasks that were once deemed impossible or too labor-intensive. By integrating laser robots into production processes, manufacturers can achieve a level of precision that enhances product quality and reduces waste, driving significant cost savings.

This technology not only streamlines workflows but also enables the customization of products on an unprecedented scale, meeting the diverse needs of a rapidly evolving market. As industries strive to remain competitive, embracing laser robots is proving to be a game-changer, paving the way for innovations that promise to further revolutionize traditional manufacturing methodologies.

Understanding Laser Robot Technology in Precision Engineering

Laser robots are transforming precision engineering by introducing unparalleled accuracy and efficiency in the manufacturing process. According to a report by Grand View Research, the global laser technology market is expected to reach $23.3 billion by 2025, driven largely by advancements in automation and robotics. These laser robots utilize cutting-edge laser systems that can switch between different tasks seamlessly, such as cutting, welding, and engraving. This capability not only reduces operational downtime but also increases the flexibility of manufacturing lines, allowing companies to adapt quickly to changing market demands.

Moreover, the precision offered by laser robots is pivotal in industries such as aerospace and automotive, where tolerances can be as tight as 0.01 millimeters. A study published by the International Journal of Advanced Manufacturing Technology highlights that implementing laser robots can lead to a 30% reduction in material waste, significantly lowering production costs and environmental impact. As manufacturers continue to seek ways to enhance their processes, the adoption of laser robot technology is likely to play a critical role in driving innovation and competitiveness in precision engineering.

Revolutionizing Manufacturing: The Impact of Laser Robots on Precision Engineering

| Feature | Description | Application Area | Benefits |

|---|---|---|---|

| High Precision | Laser robots are capable of achieving precision within microns. | Aerospace Engineering | Improved product quality and reduced waste. |

| Versatility | Can be programmed for various tasks such as cutting, welding, and engraving. | Automotive Industry | Increased efficiency and flexibility in manufacturing processes. |

| Speed | Faster operations compared to traditional methods. | Electronics Manufacturing | Higher throughput and quicker turnaround times. |

| Automation | Reduces the need for manual intervention, minimizing human error. | Medical Device Manufacturing | Consistent quality and improved safety in production. |

| Material Compatibility | Can work with a diverse range of materials, including metals and plastics. | General Manufacturing | Enhanced capability to adapt to various manufacturing needs. |

Advantages of Laser Robots in Modern Manufacturing Processes

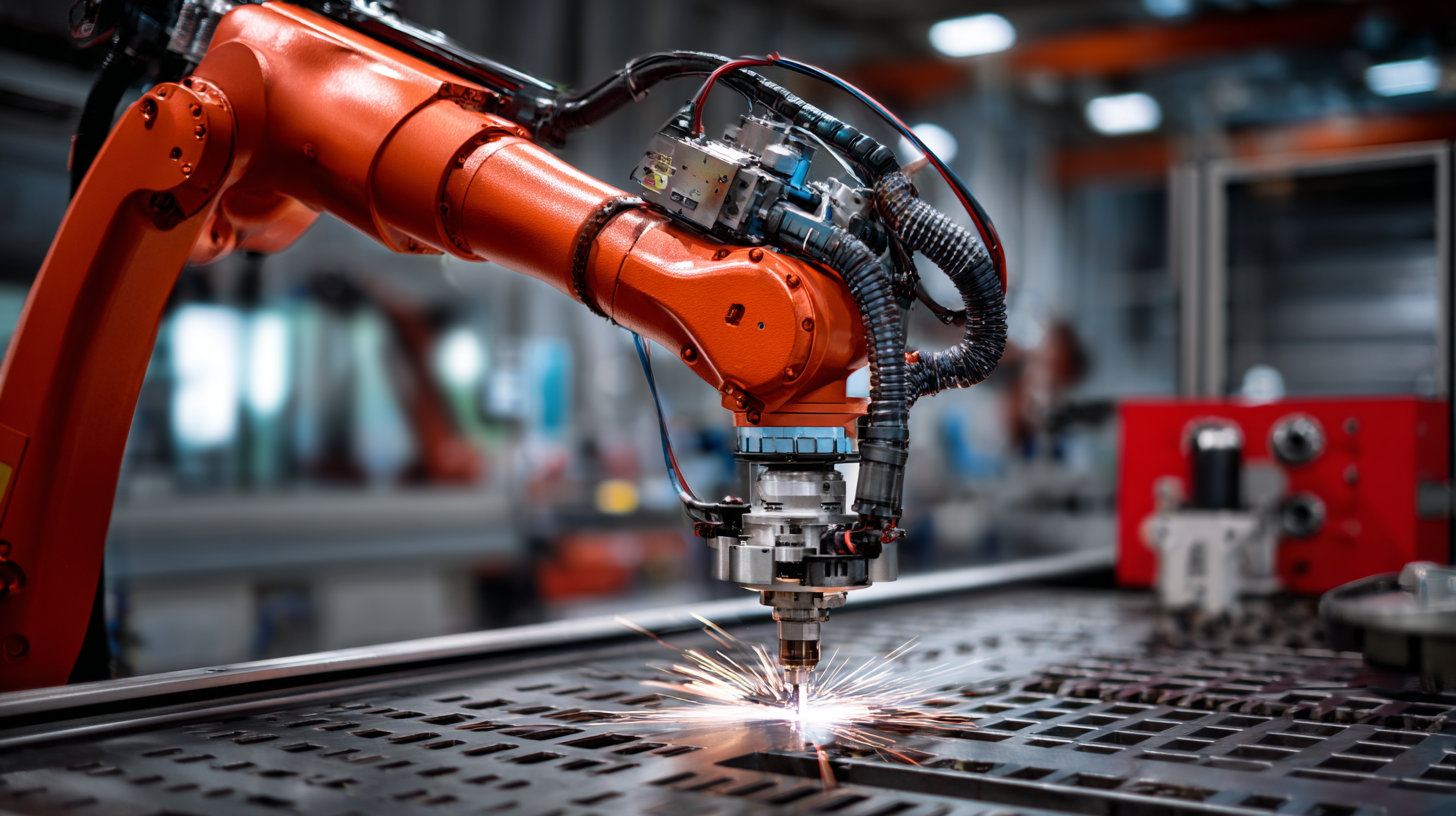

Laser robots are transforming modern manufacturing processes by enabling unprecedented levels of precision and efficiency. According to a report by Deloitte, incorporating laser technology in manufacturing can enhance productivity by up to 20%, significantly reducing operational costs while maintaining high-quality outputs. With the ability to cut, weld, and inscribe materials with extreme accuracy, laser robots minimize waste and errors, which is crucial in industries such as aerospace and automotive, where tolerances are critical.

Moreover, the flexibility of laser robots allows manufacturers to quickly adapt to changing design requirements without the need for extensive retooling. A study from MarketsandMarkets indicates that the global market for laser processing machinery is expected to reach $6.8 billion by 2025, reflecting a Compound Annual Growth Rate (CAGR) of 7.1%. This growth is driven by the increasing demand for customizable products in sectors such as electronics and medical devices. By embracing laser robots, manufacturers are not only streamlining their operations but also positioning themselves at the forefront of innovation in precision engineering.

Applications of Laser Robots Across Various Industries

Laser robots are transforming precision engineering across multiple industries, driving efficiency and accuracy to unprecedented levels. According to a report by a leading market research firm, the global robotic laser market is projected to reach $5.2 billion by 2025, with a compound annual growth rate (CAGR) of 15.3%. This rapid growth is fueled by advancements in laser technology and the increasing demand for high-tolerance manufacturing processes in sectors such as automotive, aerospace, and electronics.

Laser robots are transforming precision engineering across multiple industries, driving efficiency and accuracy to unprecedented levels. According to a report by a leading market research firm, the global robotic laser market is projected to reach $5.2 billion by 2025, with a compound annual growth rate (CAGR) of 15.3%. This rapid growth is fueled by advancements in laser technology and the increasing demand for high-tolerance manufacturing processes in sectors such as automotive, aerospace, and electronics.

In the automotive industry, laser robots are utilized for precise cutting and welding, enabling manufacturers to achieve tighter tolerances and reduce material waste. A study from the International Federation of Robotics highlights that approximately 35% of automotive manufacturing processes now employ robotic automation, with laser robots playing a critical role in enhancing production standards. Similarly, in aerospace, laser robots are essential for the fabrication of complex components, where precision is vital for safety and performance, as demonstrated by a report suggesting that laser processing can improve material yield by up to 30%.

The electronics sector also benefits from laser robots, which facilitate the production of intricate circuit boards with extreme accuracy. As outlined in a recent industry analysis, the implementation of laser cutting and marking technologies has resulted in a 25% reduction in production time and a significant decrease in error rates. These data points underline the critical role that laser robots play in modern manufacturing environments, revolutionizing how industries approach precision engineering.

Challenges and Considerations When Implementing Laser Robotics

The integration of laser robotics into precision engineering presents numerous challenges that manufacturers must navigate. One significant consideration is the initial investment required for advanced laser robotic systems. These technologies, while highly efficient and capable of producing intricate designs with unparalleled accuracy, often demand substantial capital for acquisition, installation, and training. Organizations need to evaluate whether the long-term benefits, such as reduced material waste and increased production speed, justify these upfront costs.

Another important challenge is the technical complexity associated with operating and maintaining laser robots. Skilled technicians are essential to oversee the machinery, troubleshoot issues, and ensure optimal performance. This requirement can lead to a skills gap in the workforce, necessitating additional training programs to equip employees with the necessary expertise.

Furthermore, as laser technologies advance, continuous learning and adaptation become vital to keep pace with innovations and maintain competitive advantages in the market. Thus, while laser robotics holds transformative potential for manufacturing, addressing these challenges is crucial to successful implementation.

Future Trends: The Evolution of Laser Robots in Precision Engineering

The evolution of laser robots in precision engineering marks a significant transformation in manufacturing processes. These advanced systems utilize high-powered lasers to perform intricate cutting, welding, and engraving tasks with unmatched accuracy. Unlike traditional machining methods, laser robots minimize material waste and enhance the quality of finished products. This shift not only streamlines production lines but also reduces the reliance on manual labor, leading to safer work environments and decreased operational costs.

As technology progresses, we can expect to see further integration of artificial intelligence and machine learning in laser robotic systems. These innovations will facilitate real-time adjustments during manufacturing processes, allowing for greater adaptability to varying production requirements. Additionally, the development of multi-functional laser robots capable of performing a wider range of tasks will increasingly blur the lines between different manufacturing sectors. In the future, industries such as automotive, aerospace, and healthcare will leverage these advancements to improve precision, accelerate production speeds, and innovate new product designs, ultimately reshaping the landscape of precision engineering.

Related Posts

-

Exploring the Future of Manufacturing: How Servo Robot Seam Tracking Revolutionizes Precision Welding

-

Unlocking the Future of Automation with Revolutionary Robot Software

-

Exploring the Future of Robot Servos at the 138th China Import and Export Fair in 2025

-

Exploring the Future of Robotic Laser Welding in Advanced Manufacturing Techniques

-

Transforming Industry with Intelligent Robots at the 138th Canton Fair in 2025

-

Robotic Process Innovations at the 138th Canton Fair 2025 Transforming Industry Standards in China