How to Master Robotic Arc Welding: Tips, Techniques, and Best Practices

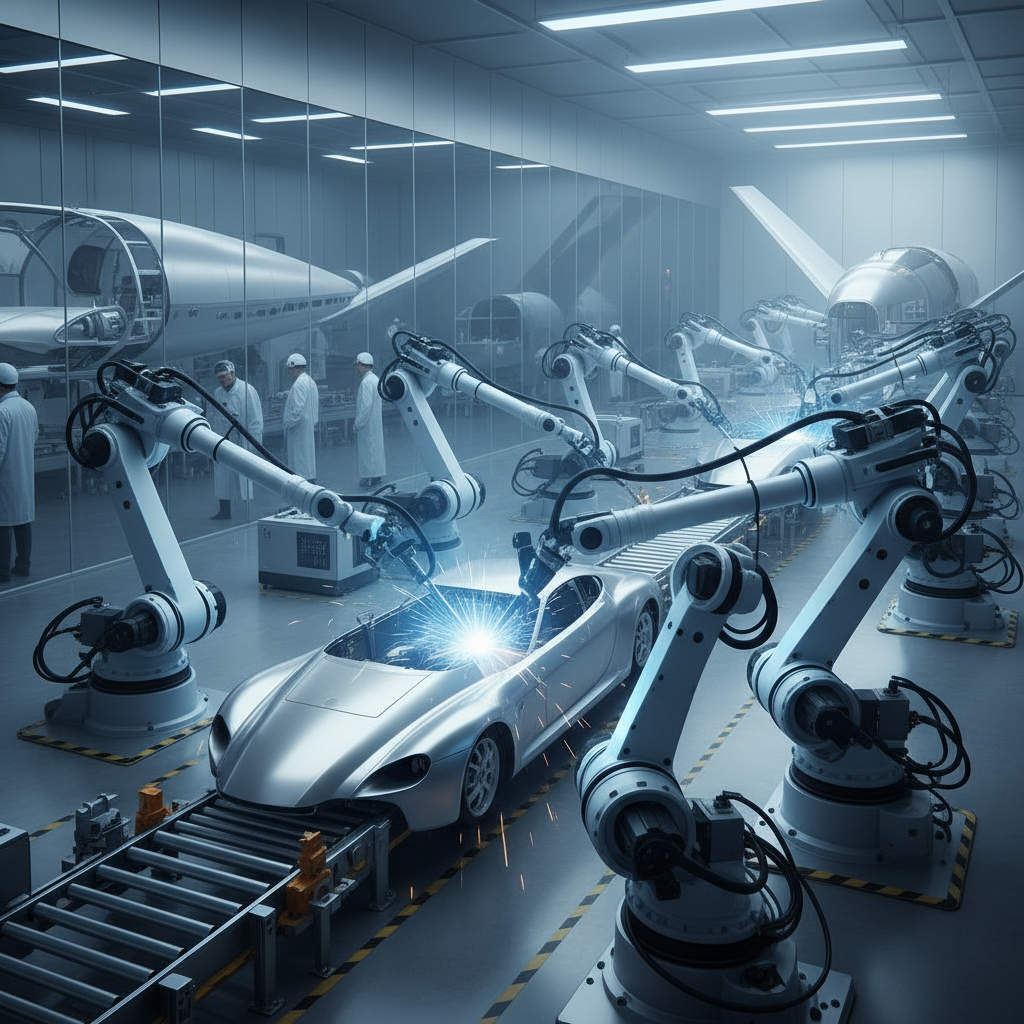

Robotic arc welding has revolutionized the manufacturing landscape, offering significant advantages in precision, efficiency, and consistency. As industries increasingly adopt automation, mastering this advanced welding technique becomes essential for professionals aiming to enhance productivity and reduce operational costs. This article will provide valuable insights into the world of robotic arc welding, equipping both novices and experienced welders with the necessary knowledge to excel in this field.

In this guide, we will delve into practical tips, cutting-edge techniques, and best practices that can elevate your robotic arc welding skills. From understanding the core components of a robotic welding system to troubleshooting common issues, each section is designed to empower you to optimize your processes and achieve superior results. Whether you are working in automotive manufacturing, aerospace, or any other industry reliant on high-quality welds, these strategies will help you harness the full potential of robotic arc welding, ensuring your work meets the highest standards of excellence.

Understanding the Basics of Robotic Arc Welding: Key Principles and Components

Robotic arc welding, a sophisticated method of joining metals through the use of automated machines, relies on a few fundamental principles and components. At its core, the process involves generating an electric arc between a welding electrode and the workpiece, causing the metal to melt and fuse. Understanding this fundamental principle is crucial for optimizing welding parameters, such as voltage and travel speed, to achieve quality welds. A successful robotic welding operation requires meticulous control of these variables, allowing for consistent results and reduced defects.

Key components of robotic arc welding systems include the welding robot itself, the power supply, the welding torch, and the workpiece manipulator. The robot executes precise movements as dictated by programmed welding paths, often utilizing advanced sensors and vision systems to enhance accuracy. The power supply delivers the necessary current to create the arc, while the welding torch feeds the electrode material into the molten weld pool. Meanwhile, the manipulation of the workpiece can be achieved through fixtures or additional robotic arms, ensuring that both the torch and the workpiece maintain optimal positioning throughout the welding process. Understanding these elements is essential to mastering robotic arc welding and achieving high-quality results in various industrial applications.

Essential Tips for Optimizing Robotic Arc Welding Efficiency and Precision

To optimize robotic arc welding efficiency and precision, it's vital to focus on a few key practices that can significantly enhance overall performance. One essential tip is to ensure that your robotic welder is correctly calibrated. Regular calibration helps maintain the accuracy of the weld and ensures that the specifications are met consistently. This includes fine-tuning the welding parameters such as voltage, wire feed speed, and travel speed according to the materials being welded.

Another effective technique is to implement a thorough pre-weld inspection process. Inspecting the components for cleanliness, fit-up, and alignment can drastically reduce defects and rework. Proper surface preparation not only enhances the quality of the weld but also prolongs the life of the welding consumables.

Finally, do not underestimate the importance of continuous training for the operators. Keeping your team updated on the latest advancements in robotic welding technology and techniques can lead to improved decision-making and problem-solving skills, ultimately boosting both efficiency and quality in the production process. Adopting these practices will certainly contribute to mastering robotic arc welding.

How to Master Robotic Arc Welding: Tips, Techniques, and Best Practices

| Aspect | Details |

|---|---|

| Welding Process | Gas Metal Arc Welding (GMAW) |

| Common Materials | Mild Steel, Stainless Steel, Aluminum |

| Key Equipment | Robot Arm, Welding Torch, Control System |

| Parameter Optimization | Voltage, Wire Feed Speed, Travel Speed |

| Safety Measures | Protective Gear, Ventilation, Emergency Cut-off |

| Quality Control | Visual Inspection, Ultrasonic Testing, X-ray Inspection |

| Maintenance | Regular Calibration, Cleaning, Component Replacement |

| Training | Operator Training Programs, Simulation Training |

Common Challenges in Robotic Arc Welding and Effective Solutions

One of the most significant challenges in robotic arc welding is ensuring proper joint fit-up. Misalignment or gaps in the workpieces can lead to welding defects, such as incomplete fusion or excessive spatter. To mitigate this, employ advanced sensing technologies to monitor and adjust the position of the components before welding. Implementing fixtures or utilizing software algorithms that guide the robotic arm based on real-time measurements can drastically improve joint accuracy and overall weld quality.

Another common issue is the inconsistency in weld bead appearance, often caused by fluctuations in welding speed or current. To address this problem, operators should focus on calibrating the welding parameters and conducting regular maintenance on the equipment. Utilizing simulation software to analyze different welding scenarios and outcomes can also help in identifying optimal settings for various materials and joint designs. Additionally, training personnel to monitor the welding process and make adjustments on the fly can enhance the reliability of robotic arc welding operations, ultimately leading to superior and more consistent results.

Best Practices for Maintaining Robotic Welding Equipment for Long-Term Productivity

Maintaining robotic welding equipment is crucial for ensuring long-term productivity and efficiency. Regular maintenance not only extends the lifespan of the machines but also enhances their performance. One best practice is to establish a routine inspection schedule. Checking key components such as welding guns, power cables, and sensors can help identify wear and tear before they lead to costly breakdowns. Keeping detailed log records of these inspections will aid in tracking maintenance history and facilitate timely interventions.

Another essential aspect is the calibration of the robotic systems. Periodically calibrating the equipment ensures that the welding parameters remain within optimal ranges, thereby producing consistent quality welds. Implementing a system for automatic calibration checks can save valuable time and enhance productivity. Additionally, ensure that all software and firmware are up to date, as updates often contain crucial improvements and security patches that can affect operational efficiency.

Investing in employee training is also vital. Skilled operators can better identify issues and perform preventative maintenance, which reduces downtime. Encouraging a culture of responsibility among staff towards equipment can lead to more conscientious handling and upkeep of the robotic systems, ultimately enhancing both productivity and quality in robotic arc welding processes.

Robotic Arc Welding Productivity Metrics

Future Trends in Robotic Arc Welding: Innovations and Industry Projections for 2025

The global welding market is set to experience significant growth in the coming years, with projections indicating a rise from $369.84 billion in 2025 to approximately $394.51 billion in 2026, and reaching around $708.03 billion by 2035. This expansion is primarily driven by the increasing adoption of advanced robotic welding technologies, which enhance precision, efficiency, and safety across various industries, including automotive and aerospace. The projected compound annual growth rate of 6.41% from 2025 to 2035 highlights the escalating demand for innovative welding solutions.

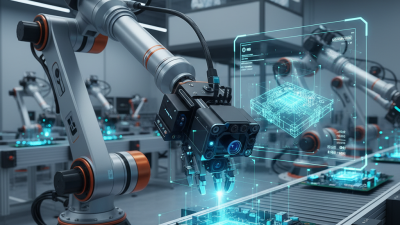

As the robotics industry continues to evolve, there is a notable trend towards intelligent welding robots, which have emerged as key players in the market. These sophisticated machines are not only capable of executing micro-level weld seams with high accuracy but also adapt to different welding techniques and materials seamlessly. Their ability to boost production rates while minimizing errors positions them as invaluable assets in modern manufacturing environments. With robotics making strides in sectors like education, healthcare, and urban management, the potential for welding robots is immense, making them the "darling" of the market.

Related Posts

-

Exploring the Future of Robotic Laser Welding in Advanced Manufacturing Techniques

-

Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry

-

Why Robotic Welding Systems Are Revolutionizing the Manufacturing Industry Today

-

What is Robotic Vision? Understanding Its Importance and Applications in Automation

-

The Future of Healthcare Automation How Dispensing Robots Are Revolutionizing Patient Care

-

Exploring the Future of Robotic Vision: Innovations That Transform Industries