Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry

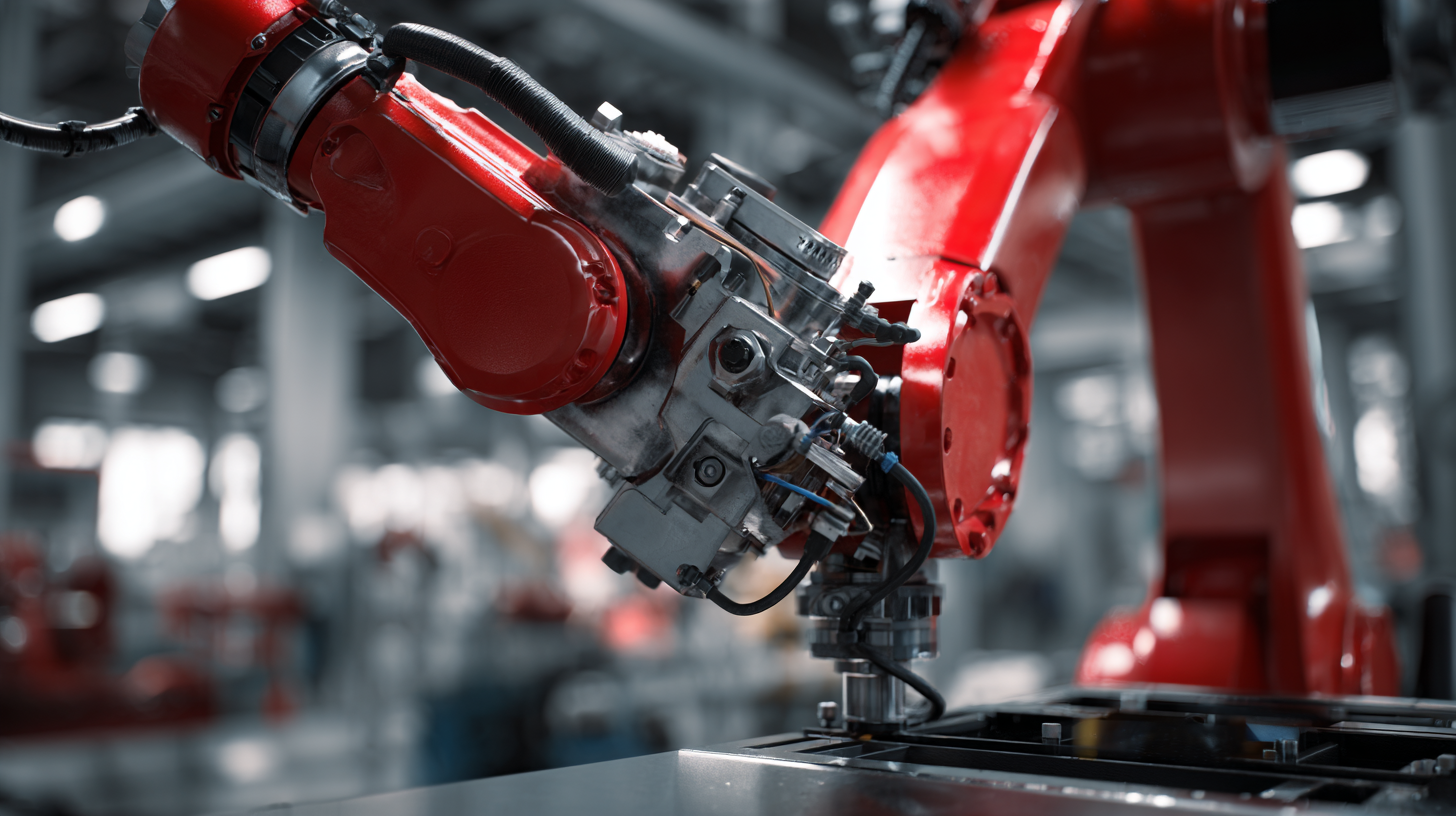

As we venture into a new era of manufacturing, the role of technology is becoming increasingly indispensable. Among the myriad of innovations reshaping the industry,

welding robots stand out as crucial players in redefining efficiency, quality, and productivity. According to

Dr. Emily Chang, a leading expert in robotic automation, "Welding robots are not merely tools; they are transformative agents that

elevate the standard of manufacturing by ensuring precision and consistency at unprecedented speeds." This sentiment captures the essence of why

welding robots are pivotal in the ever-evolving landscape of manufacturing.

The integration of welding robots into production lines is revolutionizing how industries operate, pushing them towards greater automation and reduced labor costs.

These advanced machines have the capacity to perform complex welding tasks with remarkable accuracy, minimizing human error while maximizing output. As competition

intensifies, manufacturers are increasingly turning to welding robots to enhance their operational capabilities, underscoring the growing significance of this technology.

In this exploration of the future of manufacturing, we will delve into the top five ways welding robots are transforming the industry. From improving safety standards

to optimizing production processes, the impact of welding robots is far-reaching and set to shape the future of manufacturing for years to come.

Understanding the Role of Welding Robots in Modern Manufacturing Processes

Welding robots are becoming integral to modern manufacturing processes, significantly enhancing efficiency and precision. These advanced machines are capable of performing complex welding tasks at a rapid pace while maintaining consistency that is often challenging for human workers to achieve. With the ability to operate continuously without fatigue, welding robots ensure high-quality welds, thereby reducing the risk of defects and improving overall output.

Welding robots are becoming integral to modern manufacturing processes, significantly enhancing efficiency and precision. These advanced machines are capable of performing complex welding tasks at a rapid pace while maintaining consistency that is often challenging for human workers to achieve. With the ability to operate continuously without fatigue, welding robots ensure high-quality welds, thereby reducing the risk of defects and improving overall output.

Moreover, the incorporation of welding robots in manufacturing allows for greater flexibility in production lines. Manufacturers can easily reprogram these robots to accommodate different welding tasks, making it easier to adapt to changing market demands. This adaptability not only streamlines production but also minimizes downtime, ensuring that companies remain competitive in a fast-evolving industrial landscape. As welding technology continues to advance, robots are expected to play an even more pivotal role in shaping the future of manufacturing, driving innovation and redefining operational standards.

Key Technologies Driving the Adoption of Welding Automation in Industries

The adoption of welding automation in the manufacturing sector is being propelled by several key technologies that address long-standing challenges. With the welding equipment market projected to grow from $1.59 billion in 2025 to $2.72 billion by 2033, at a compound annual growth rate (CAGR) of 6.9%, industries are increasingly turning to intelligent robotic solutions. These advancements significantly mitigate issues such as the reliance on manual labor, inconsistent welding quality, and worker hazards in extreme environments.

Recent innovations have elevated the capabilities of welding robots, transforming them from teachable machines to autonomous entities. This shift is exemplified by breakthroughs in artificial intelligence that allow robots to understand and optimize welding seams, enhancing both precision and efficiency. As manufacturers embrace these technologies, the integration of automation in welding processes is set to not only streamline production but also redefine operational standards in the industry, marking a critical evolution in manufacturing practices.

Benefits of Integrating Welding Robots into Production Lines for Efficiency

The integration of welding robots into production lines is transforming the manufacturing landscape, offering numerous benefits that enhance operational efficiency. According to recent market analysis, the global robotics technology market is projected to grow substantially, reaching approximately USD 375.95 billion by 2025. This growth is largely driven by advancements in automation and precision engineering, particularly in the automotive sector, where the adoption of welding robots is significantly on the rise.

Welding robots, including collaborative robots (cobots), are designed to work alongside human operators, performing repetitive tasks that maximize productivity while minimizing physical strain on workers. Reports indicate that the automotive robotics market is poised for explosive growth, partially fueled by the need for increased efficiency in electric vehicle production. These robots not only streamline processes but also ensure consistent quality, reducing production errors and waste.

**Tips:** To leverage the full benefits of welding robots, manufacturers should prioritize training programs for operators to enhance human-robot collaboration. Additionally, investing in adaptive automation technologies can further optimize production lines by allowing for greater flexibility in response to changing market demands. Emphasizing safety protocols is also essential to create a smooth integration of robotic systems within existing workflows.

Efficiency Benefits of Integrating Welding Robots into Production Lines

Challenges in Implementing Welding Robots and Strategies to Overcome Them

The integration of welding robots in the manufacturing sector presents several challenges that companies must navigate to fully harness their potential. One significant hurdle is the initial investment required for robotics technology. Many manufacturers may be hesitant to allocate a substantial budget for automation, fearing it may take too long to see a return on investment. To address this, businesses can explore leasing options for robotic systems, thus spreading out costs and minimizing financial risk.

Another challenge is the skill gap in the workforce. Existing employees may lack the training needed to operate and maintain advanced robotic systems. To overcome this barrier, companies should invest in robust training programs that equip staff with the necessary skills to work alongside robots. Encouraging a culture of continuous learning can significantly ease the transition process.

**Tips:** Regular workshops and hands-on training can enhance employee engagement and confidence. Collaborating with educational institutions to create specialized courses in robotics can also help build a skilled workforce ready to support automation initiatives. By prioritizing these strategies, manufacturing firms can not only implement welding robots successfully but also position themselves as leaders in an evolving industry.

Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry

| Dimension | Data |

|---|---|

| Adoption Rate of Welding Robots (2023) | 21% |

| Cost Reduction from Automation | 30% on average |

| Productivity Increase | 40% increase |

| Common Challenges in Implementation | Skill gaps, high initial costs, integration issues |

| Strategies to Overcome Challenges | Training programs, phased implementation, ROI analysis |

| Expected ROI Timeframe | 2-3 years |

| Growth in Welding Robot Market (2023-2028) | 12% CAGR |

Future Trends in Welding Robotics and Their Impact on Manufacturing Innovation

The welding industry, traditionally reliant on manual labor, is undergoing a transformative shift with the integration of robotics. Future trends in welding robotics indicate a surge in automation, driven by advancements in AI and machine learning. These technologies equip welding robots with enhanced precision, capable of executing complex welds with minimal human intervention. As these robots become more sophisticated, they not only increase productivity but also reduce the margin for error, leading to higher quality outputs.

Moreover, the impact of welding robotics on manufacturing innovation extends beyond efficiency. The adaptability of modern welding robots allows manufacturers to easily switch between different tasks and projects, enabling a more agile production process. This agility is crucial in today’s fast-paced market, where customization and rapid response to customer demands are essential. Consequently, the shift towards robotic solutions is paving the way for a more resilient manufacturing landscape, capable of supporting diverse applications while maintaining cost-effectiveness and operational excellence.

Related Posts

-

Exploring the Future of Manufacturing: How Servo Robot Seam Tracking Revolutionizes Precision Welding

-

Exploring the Future of Robotic Laser Welding in Advanced Manufacturing Techniques

-

Revolutionizing Metal Fabrication with Seam Tracking Welding Technology for Precision Parts Production

-

Exploring the Future of Robotic Vision: Innovations That Transform Industries

-

Exploring the Future of Robotic Process Automation for Business Efficiency

-

Exploring the Future of Robot Servos at the 138th China Import and Export Fair in 2025