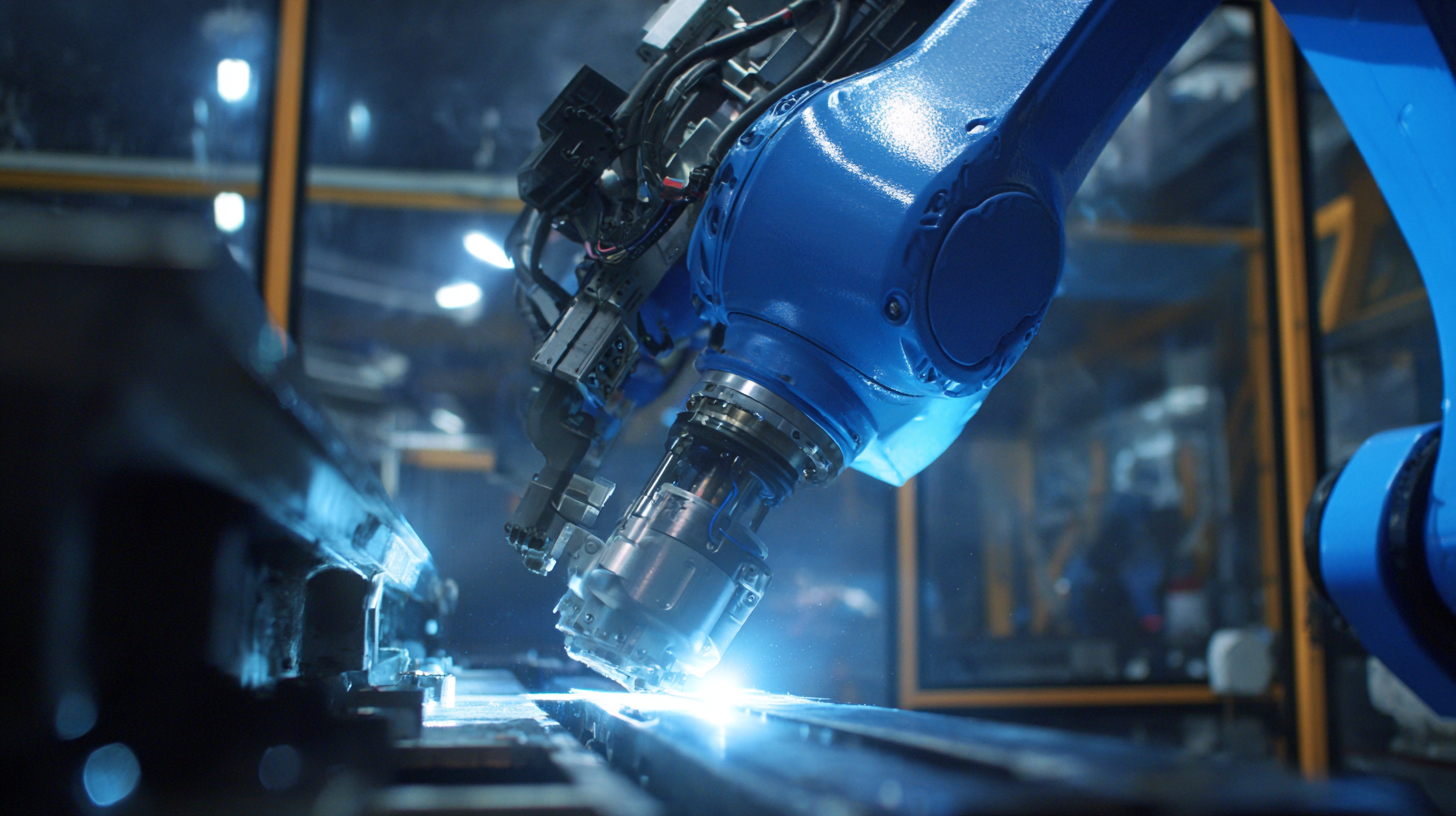

Exploring the Future of Manufacturing: How Servo Robot Seam Tracking Revolutionizes Precision Welding

The manufacturing industry is undergoing a profound transformation, with advancements in automation technology reshaping traditional processes. One of the key innovations driving this change is "servo robot seam tracking," a technique that enhances precision and efficiency in welding operations. According to a report by MarketsandMarkets, the global industrial robotics market is expected to reach $64.3 billion by 2026, growing at a CAGR of 10.5%. This surge is largely attributable to the integration of smart technologies, such as servo robot seam tracking systems, which allow for real-time adjustments to maintain optimal welding paths, reduce errors, and improve structural integrity. As manufacturers strive for higher productivity and lower operational costs, the adoption of these cutting-edge robotic solutions is set to revolutionize the landscape of precision welding, ensuring quality and consistency across various sectors of the economy.

Understanding Servo Robot Technology in Manufacturing

Servo robot technology is redefining the landscape of manufacturing, particularly in the realm of precision welding. By utilizing advanced servo motors and sophisticated control algorithms, these robots can achieve unparalleled accuracy in seam tracking. This capability enhances the welding process by consistently ensuring that the welding torch remains aligned with the joint, compensating for any variations in material surfaces or positions. Consequently, manufacturers can expect higher quality welds, reduced material waste, and minimized rework, which significantly improves overall productivity and cost-efficiency.

Moreover, the integration of servo robot technology into manufacturing systems paves the way for increased automation. As industries strive for greater flexibility and responsiveness to market demands, servo robots can easily adapt to different welding tasks without extensive reprogramming. Their ability to operate tirelessly and with high repeatability allows manufacturers to run production lines continuously, thereby meeting tight deadlines and fulfilling large orders. The innovative features of servo robots not only enhance the precision of welding processes but also contribute to the long-term sustainability and growth of the manufacturing sector.

Exploring the Future of Manufacturing: Servo Robot Technology in Precision Welding

The Role of Seam Tracking in Precision Welding Techniques

Seam tracking technology has become a pivotal element in precision welding, enhancing the quality and efficiency of manufacturing processes. According to a report by Research and Markets, the global welding robotics market is predicted to grow at a CAGR of 9.93% from 2021 to 2026, largely driven by advancements in automation, including sophisticated seam tracking techniques. These technologies allow robots to accurately identify and follow weld seams, adapting in real time to variations in material alignment and surface integrity, which is crucial for achieving consistent weld quality.

Moreover, the accurate tracking of seams significantly reduces the likelihood of defects and rework. A study by the International Journal of Advanced Manufacturing Technology found that precision welding with advanced seam tracking can decrease defect rates by up to 50%, translating into substantial cost savings and improved production timelines. As manufacturers increasingly adopt these innovative technologies, the integration of servo robots equipped with advanced seam tracking systems not only enhances operational efficiency but also raises the standards for precision in welding applications, setting new benchmarks in the industry.

Advantages of Using Servo Robots for Enhanced Welding Accuracy

The integration of servo robots in manufacturing processes is transforming precision welding by significantly enhancing accuracy. These advanced robotic systems employ sophisticated seam tracking technologies, allowing them to adapt to variations in workpiece geometry in real time. This adaptability ensures that the welding torch stays precisely aligned with the seam, leading to superior weld quality and reduced defects. As a result, manufacturers can achieve tighter tolerances and improve the overall structural integrity of their products.

Additionally, servo robots offer increased operational efficiency. By automating the welding process, these robots can consistently deliver high-speed performance while maintaining quality control. This not only minimizes the need for manual intervention but also reduces the likelihood of human error. Furthermore, servo robots are designed to optimize energy consumption and reduce waste, which contributes to a more sustainable manufacturing environment. The combination of precision, efficiency, and sustainability positions servo robots as a game-changer in the welding industry, paving the way for manufacturers to meet the growing demands of modern production.

Implementing Servo Robot Automation in Manufacturing Processes

The implementation of servo robot automation in manufacturing processes is transforming precision welding techniques. By utilizing advanced servo motor technology, manufacturers can enhance accuracy and consistency in welding applications. This automation not only minimizes human error but also significantly boosts production speed, allowing for higher throughput in manufacturing environments. The integration of servo-driven systems enables manufacturers to perform complex welding tasks that would be challenging with traditional methods.

Moreover, the growth of the servo drives market reflects the increasing demand for such automation solutions. With a projected CAGR of around 5.2%, the market is witnessing innovations that cater to both AC and DC servo drives across various voltage ranges. This trend underscores the industry's shift towards more efficient and intelligent manufacturing practices, positioning automation as a critical component for competitiveness in the global market. Such advancements lead to increased operational efficiency, reduced costs, and improved product quality, shaping the future landscape of manufacturing.

Future Trends in Servo Technology and Their Impact on Welding Industry

The future of servo technology promises to significantly impact the welding industry, particularly through advancements in servo robot seam tracking.

As manufacturing processes continue to evolve, precision welding stands at the forefront of these innovations.

Servo robots equipped with advanced seam tracking capabilities allow for real-time adjustments and corrections during the welding process.

This not only enhances the accuracy of welds but also increases efficiency, resulting in higher quality products and reduced material wastage.

Servo robots equipped with advanced seam tracking capabilities allow for real-time adjustments and corrections during the welding process.

This not only enhances the accuracy of welds but also increases efficiency, resulting in higher quality products and reduced material wastage.

Emerging trends indicate a shift towards more adaptive and intelligent manufacturing environments. The integration of AI and machine learning with servo technology is paving the way for robots to learn from their environments and optimize welding parameters dynamically. As a result, manufacturers can expect reduced downtime and improved flexibility, allowing for customization and quick adaptation to changing production demands. This adaptability is crucial in an era where personalized products are gaining popularity, and businesses require fast turnaround times without compromising on quality.

Related Posts

-

Unlocking the Future of Automation with Digital Robotic Process Techniques

-

Exploring the Future of Robotic Vision: Innovations That Transform Industries

-

Transforming Industry with Intelligent Robots at the 138th Canton Fair in 2025

-

Robotic Process Innovations at the 138th Canton Fair 2025 Transforming Industry Standards in China

-

How to Enhance Your Photography Skills with Innovative Camera Robots

-

Unlocking the Future of Automation with Revolutionary Robot Software