Unlocking the Future of Automation with Revolutionary Robot Software

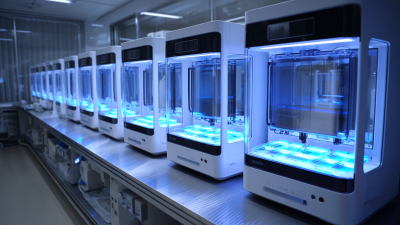

As we stand on the brink of a technological revolution, the evolution of robot software is set to redefine the landscape of automation across various industries. This innovative software not only enhances the capabilities of robots but also unlocks new possibilities for efficiency and productivity. In this article, we will delve into the transformative power of revolutionary robot software, exploring how it integrates advanced algorithms, machine learning, and artificial intelligence to create more autonomous and intelligent machines. We'll discuss practical tips and strategies for businesses looking to implement these cutting-edge solutions, providing insights into optimizing operations and maximizing return on investment. Join us as we uncover the future of automation, where robot software is not just a tool but a vital partner in driving progress and innovation.

The Evolution of Robot Software: Paving the Way for Future Automation

The evolution of robot software has been a game-changer in the realm of automation, driving industries toward unprecedented efficiency and accuracy. According to a report by the International Federation of Robotics, the global industrial robot stock is projected to reach 4 million units by 2025, reflecting an annual growth rate of 10%. This surge is attributed to advancements in software that enhance the capabilities of robots, allowing them to perform complex tasks with precision and adapt to various production environments.

As industries continue to integrate more sophisticated robotic systems, it is crucial to stay ahead of the curve. Tip: Invest in training for your workforce on the latest robotic software and automation tools to ensure a smooth transition and maximize productivity. Companies that prioritize employee training can see a 30% increase in operational efficiency, according to a study by McKinsey & Company.

Moreover, the integration of artificial intelligence (AI) within robotic systems is transforming the landscape. A significant portion of industry leaders, around 70%, are now adopting AI-driven robots to enhance decision-making processes and improve overall system performance. Tip: Consider partnering with software developers specializing in AI to customize solutions that align with your specific operational needs, unlocking the full potential of automation in your business.

Understanding the Key Technologies Behind Revolutionary Robot Software

Revolutionary robot software is transforming the landscape of automation, driven by advancements in several key technologies. One of the cornerstones of this evolution is artificial intelligence (AI), which enables robots to learn from their environment and adapt to changing conditions. Through machine learning algorithms, robots can analyze vast amounts of data to improve their efficiency and decision-making capabilities. This ability to learn and evolve not only enhances the performance of robots but also expands their application across diverse industries, from manufacturing to healthcare.

Another critical component of robotic software innovation is the integration of advanced sensors and IoT connectivity. Sensors provide robots with real-time feedback about their surroundings, allowing for precise navigation and interaction with objects. Meanwhile, IoT connectivity facilitates seamless communication between robots and other devices, creating an interconnected ecosystem that enhances productivity and safety. This synergy between AI, sensors, and IoT is paving the way for the development of autonomous systems capable of performing complex tasks with minimal human intervention, heralding a new era in automation.

Unlocking the Future of Automation with Revolutionary Robot Software

This chart illustrates the relative impact of key technologies driving revolutionary robot software. Machine Learning stands out as the most significant factor, followed by Computer Vision and Natural Language Processing, highlighting the multidisciplinary nature of advancements in automation.

Benefits of Advanced Robot Software in Streamlining Industrial Processes

The advent of advanced robot software is revolutionizing industrial processes, offering unprecedented efficiency and productivity. By automating repetitive tasks, this cutting-edge technology minimizes human error and speeds up production lines, allowing businesses to meet growing demands without sacrificing quality. These software systems can also adapt to various tasks, making them versatile tools within manufacturing settings. With next-gen features like machine learning and real-time data analytics, robots can optimize their performance dynamically, ensuring that operations remain seamless and responsive to market changes.

Challenges and Solutions in Implementing Cutting-Edge Robot Automation

The rapid advancement of robotic automation holds great promise, yet it is accompanied by significant challenges in implementation. One of the primary hurdles is the integration of new software with existing systems. Many companies rely on legacy technologies that can be incompatible with the latest automation solutions. This disconnect often leads to increased costs and delayed project timelines. To navigate these challenges, organizations can focus on modular design, allowing for incremental updates that seamlessly integrate with current infrastructures.

Another critical challenge in deploying cutting-edge robot automation is the workforce adaptation. Employees may fear job displacement due to automation, leading to resistance against new technologies. To address this, businesses should prioritize reskilling their workforce, equipping employees with the necessary tools and knowledge to work alongside robots effectively. By fostering a culture of collaboration between human workers and robotic systems, companies can not only enhance productivity but also create a more engaged workforce, ultimately unlocking the full potential of robotic automation.

Unlocking the Future of Automation with Revolutionary Robot Software - Challenges and Solutions in Implementing Cutting-Edge Robot Automation

| Challenge | Description | Solution | Impact |

|---|---|---|---|

| Integration Complexity | Combining new software with existing infrastructure can be difficult. | Use modular designs for easier integration. | Enhanced compatibility and reduced downtime. |

| Skill Gap | Lack of trained personnel can hinder implementation. | Invest in training programs and partnerships with educational institutions. | Increased workforce capabilities and versatility. |

| High Initial Cost | Initial investment in robotic software and hardware can be substantial. | Explore financing options and ROI analysis tools. | More informed financial decisions and potential cost savings. |

| Regulatory Compliance | Adhering to industry regulations can be challenging. | Stay informed on regulations and incorporate compliance by design. | Reduced legal risks and smoother operations. |

| Maintenance and Upkeep | Ongoing maintenance of robotic systems can be resource-intensive. | Implement predictive maintenance strategies. | Increased uptime and lower long-term costs. |

The Impact of AI Integration on the Future of Robot Software Development

The integration of artificial intelligence (AI) into robot software development is profoundly transforming the landscape of automation. According to a report by McKinsey & Company, up to 70% of jobs could be affected by automation technologies, highlighting the necessity for sophisticated robot software that can adapt and perform complex tasks. AI-driven robots are no longer limited to simple repetitive actions; they are evolving to handle intricate scenarios requiring decision-making and flexibility, thus enhancing their utility across various industries.

In addition, the International Federation of Robotics (IFR) projects a growth rate of 26% annually in the global robotics market, which is spurred significantly by advancements in AI. The integration of AI enables robots to learn from their experiences, improving their performance over time and allowing for predictive maintenance and increased operational efficiency. This capability is particularly critical in industries such as manufacturing, healthcare, and logistics, where agility and precision can provide a competitive edge. As companies continue to recognize the importance of AI in driving their automation strategies, the future of robot software development is poised for unprecedented innovation and growth.

Related Posts

-

Transforming Industry with Intelligent Robots at the 138th Canton Fair in 2025

-

Unlocking the Future of Automation with Advanced Robot Vision Systems

-

Robotic Process Innovations at the 138th Canton Fair 2025 Transforming Industry Standards in China

-

The Future of Healthcare Automation How Dispensing Robots Are Revolutionizing Patient Care

-

Exploring the Future of Robot Servos at the 138th China Import and Export Fair in 2025

-

Unlocking the Future of Automation with Digital Robotic Process Techniques