2025 How to Enhance Robotic Performance with 3D Vision Systems in Automation

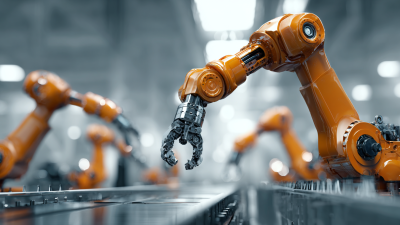

In the rapidly evolving landscape of automation, the integration of 3D vision systems for robots is poised to revolutionize operational efficiency and precision. According to a recent report by MarketsandMarkets, the global 3D machine vision market is expected to reach $7.5 billion by 2025, growing at a CAGR of 12.6%. This growth is largely driven by the increasing demand for automation across various industries, from manufacturing to logistics, where accuracy and speed are paramount. The integration of 3D vision systems allows robots to perceive their environment in three dimensions, enabling them to navigate complex tasks with enhanced capability and reduced errors.

As industry expert Dr. Maria Thompson emphasizes, “The implementation of 3D vision systems for robots not only enhances their ability to understand and interact with their environment but also significantly increases productivity by minimizing operational downtime.” This statement underscores the critical role that advanced vision systems play in maximizing the potential of robotic automation. By leveraging sophisticated imaging technologies, organizations can streamline their processes and achieve higher levels of automation, thus positioning themselves competitively in an increasingly automated marketplace. As we explore the strategies to enhance robotic performance through 3D vision systems, it becomes clear that adopting such technologies is not merely an option but a necessity for future success in automation.

Benefits of Integrating 3D Vision Systems in Robotic Automation

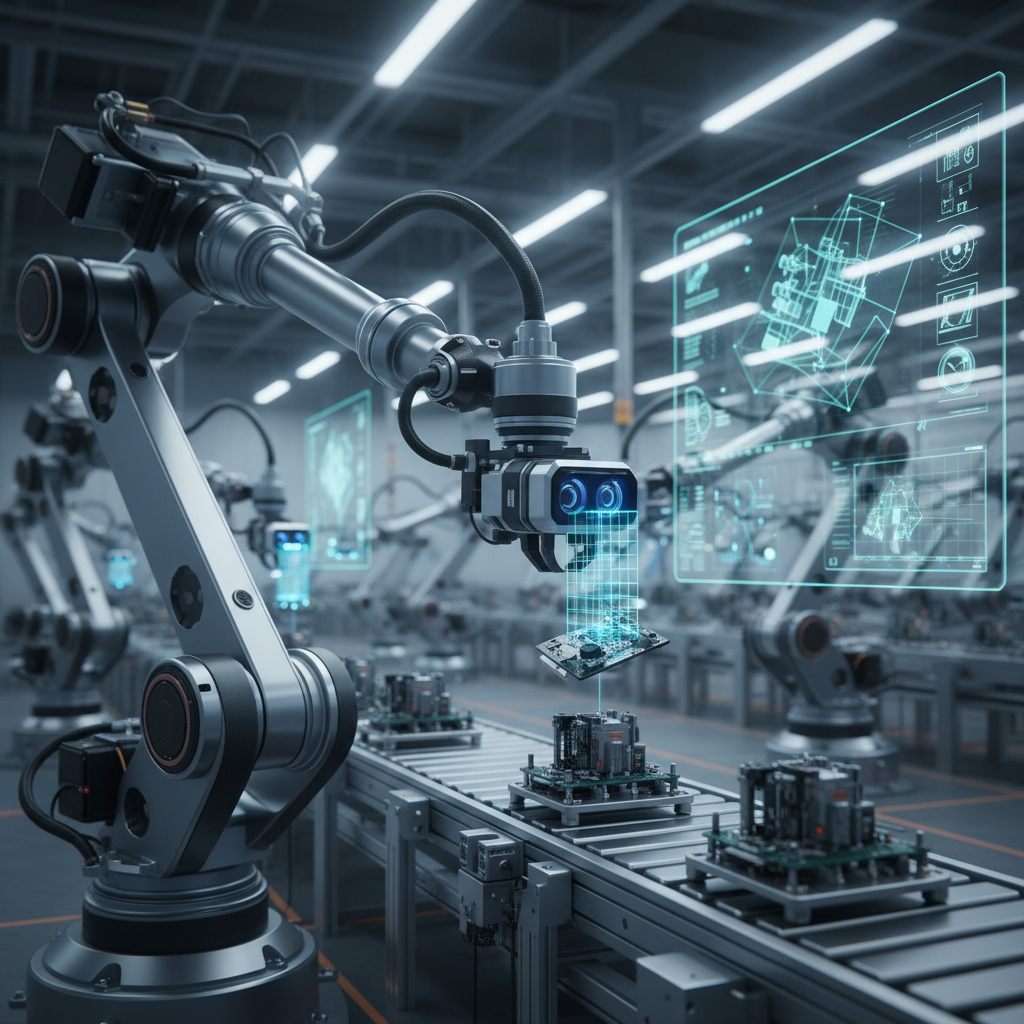

The integration of 3D vision systems in robotic automation is revolutionizing manufacturing and significantly enhancing operational efficiency. As the market for automated systems grows, projected to reach $150 billion by 2025, manufacturers are increasingly investing in advanced technologies. 3D vision systems offer accurate spatial perception, enabling robots to identify and manipulate objects with unprecedented precision. This capability allows for real-time adjustments in production lines, reducing errors and downtime, thus optimizing throughput and scalability.

The benefits of implementing 3D vision in robotic systems extend beyond increased accuracy; they also contribute to operational flexibility. With the ability to adapt to various tasks without extensive reprogramming, these automated systems can accommodate diverse product lines, which is essential in today’s fast-paced manufacturing environment. Reports indicate that businesses adopting such technologies can enhance productivity by up to 30%, driving growth in market share and competitiveness.

The demand for 3D vision integration in robotic automation is a clear indicator of its potential to transform production processes, leading to smarter and more efficient manufacturing solutions.

Key Technologies Behind 3D Vision Systems in Robotic Applications

The global 3D machine vision market is anticipated to grow significantly, projected to rise from $3.92 billion in 2024 to $8.44 billion by 2032, showcasing a compound annual growth rate (CAGR) of 10.1%. This rapid expansion indicates a robust demand for enhanced robotic performance through advanced 3D vision systems. Key technologies driving this development include 3D digital image acquisition, laser scanning, and advanced mapping techniques which play critical roles in automating robotic inspections across various industries.

Recent advancements in the sector have seen exciting moves from leading companies. For instance, a notable player recently announced significant performance improvements and is positioned to emerge as a frontrunner in the global 3D vision solutions market. Companies are increasingly integrating 3D vision capabilities within their robotics applications, leveraging artificial intelligence to transform operational efficiencies. With substantial investments, like the successful C+ round financing for a domestic tech firm, the focus on 3D vision perception robots is set to elevate the industry, paving the way for smarter and more capable automated systems in the near future.

Challenges in Implementing 3D Vision for Robotics in Industry

The implementation of 3D vision systems in robotics presents several challenges that industries must navigate to fully harness their potential. One of the primary obstacles is the integration of these advanced systems with existing robotic platforms. According to a report by ABI Research, the global market for 3D vision technology in industrial automation is projected to surpass $1.5 billion by 2025, highlighting the growing interest in these technologies. However, the integration process can be complex, requiring significant software updates and hardware compatibility assessments, which can deter small to medium-sized enterprises from making the leap.

Another challenge lies in the processing demands of 3D vision systems. The vast amounts of data generated require powerful computing capabilities and advanced algorithms to ensure real-time performance. As highlighted in a study by MarketsandMarkets, about 30% of companies reported data processing speed as a key barrier when adopting 3D vision in their robotic applications. This not only necessitates investment in high-performance computing but also calls for skilled personnel proficient in software development and robotics with a strong foundation in machine learning and computer vision. Consequently, while 3D vision systems offer substantial benefits, addressing these hurdles is essential for optimal implementation in industrial robotics.

2025: Challenges in Implementing 3D Vision Systems for Robotics in Industry

Case Studies: Successful 3D Vision Integration in Automated Systems

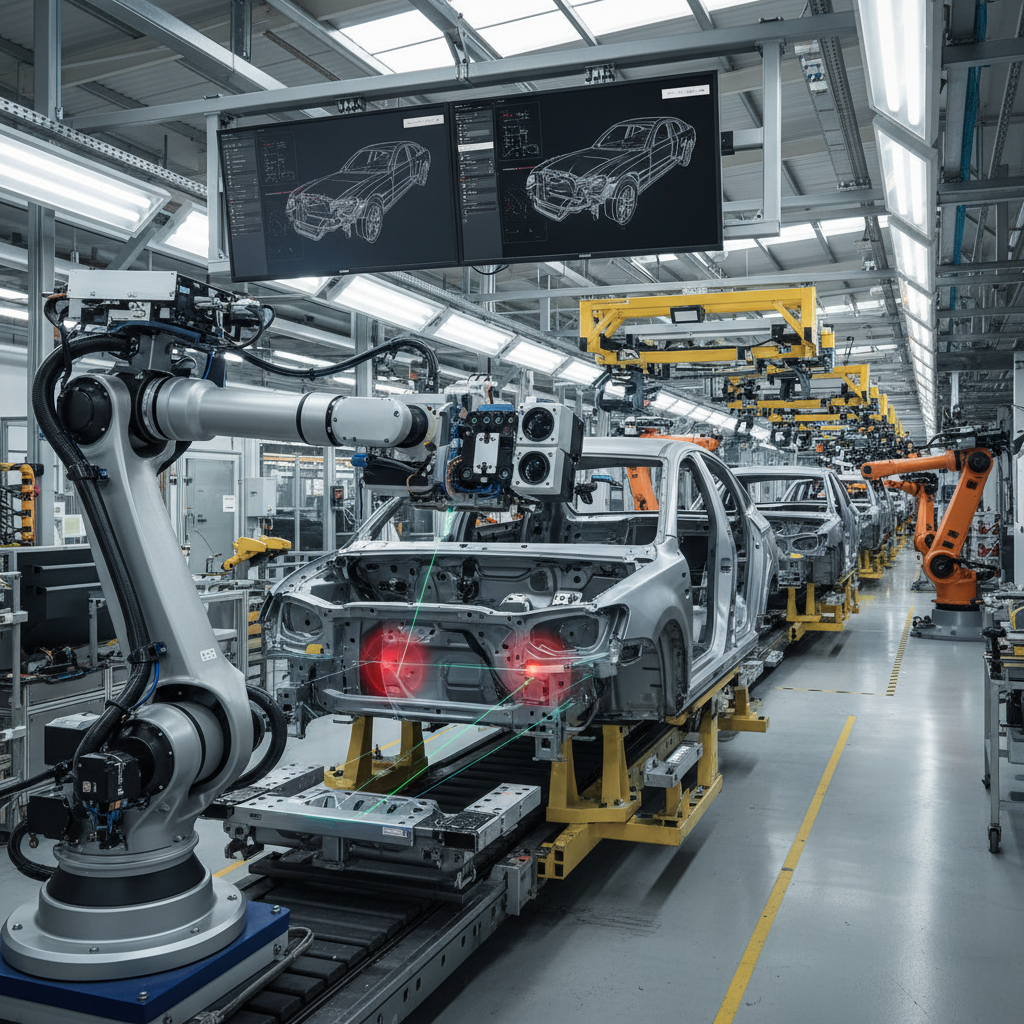

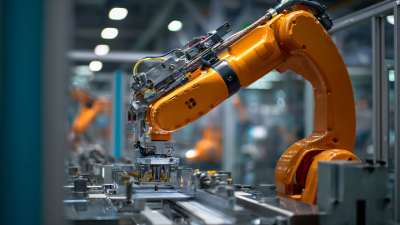

The integration of 3D vision systems in automated environments has proven to drive remarkable enhancements in robotic performance. One compelling case study involves an automotive manufacturing line that utilized 3D vision technology to optimize quality control. By deploying high-resolution cameras capable of capturing intricate details, the system could detect defects in real-time, ensuring only flawless components proceeded through the assembly process. This not only reduced waste but also eliminated costly downtimes associated with manual inspections.

Another illustrative example comes from the food processing industry, where a 3D vision system was integrated into packaging robots. The technology enabled robots to assess the size, shape, and orientation of various products, allowing for precise handling during stacking and sorting. As a result, the operation saw increased speed and efficiency, effectively minimizing damage to delicate items. These successful implementations underline the transformative potential of 3D vision systems in enhancing automation, showcasing how advanced visual capabilities can lead to substantial improvements in both productivity and accuracy across different sectors.

Future Trends: Advancements in 3D Vision for Enhanced Robot Performance

As we step into 2025, the integration of 3D vision systems in automation is set to revolutionize robotic performance. According to a recent report by MarketsandMarkets, the 3D vision market is projected to reach $5.3 billion by 2026, driven by advancements in machine learning and sensor technologies. These innovations are empowering robots to process and analyze spatial data with unprecedented accuracy, enabling them to perform complex tasks in dynamic environments.

Tips for enhancing robotic effectiveness with 3D vision systems include investing in quality imaging technologies, such as stereo vision and LiDAR, which can significantly improve depth perception and object recognition capabilities. Additionally, implementing robust algorithms that leverage deep learning can help robots adapt to varying conditions, thus optimizing their operational efficiency.

Future trends indicate that the coming years will see a surge in collaborative robots (cobots) equipped with advanced 3D vision capabilities. A report by Zion Market Research highlights that the cobot market could grow to $12.3 billion by 2028, emphasizing the importance of 3D vision in making these systems safer and more efficient. Adopting 3D vision in industrial settings not only enhances productivity but also reduces the risk of accidents, ultimately fostering a more reliable automation framework.

Related Posts

-

Top 10 Amazing Innovations in Robot Vision Technology You Need to Know

-

Unlocking the Future of Automation with Revolutionary Robot Software

-

Revolutionizing Industries: How Robot Vision Systems Enhance Automation and Efficiency

-

Exploring the Future of Robotic Laser Welding in Advanced Manufacturing Techniques

-

Revolutionizing Metal Fabrication with Seam Tracking Welding Technology for Precision Parts Production

-

Revolutionizing Manufacturing: The Impact of Laser Robots on Precision Engineering