How to Choose the Right Inspection Robot for Your Industry Needs

As industries continue to evolve in an increasingly competitive landscape, the demand for automation and efficiency has never been more critical. Inspection robots have emerged as pivotal tools in maintaining quality control, ensuring safety, and enhancing operational productivity across various sectors. According to a recent report by MarketsandMarkets, the global inspection robot market is projected to grow from USD 2.5 billion in 2021 to USD 5.0 billion by 2026, reflecting a compound annual growth rate (CAGR) of 15.4%. This rapid expansion underscores the importance of selecting the right inspection robot tailored to specific industry needs, as these machines are instrumental in reducing human error and improving process reliability.

The versatility of inspection robots spans diverse applications, from manufacturing and oil and gas to healthcare and food safety. In the manufacturing sector alone, up to 60% of companies are now integrating robotic solutions to streamline their inspection processes, which can dramatically cut inspection times and costs. However, choosing the right inspection robot involves more than just capital investment; it requires a thorough understanding of the operational environment, the types of inspections needed, and the specific capabilities of the robots available. This article will explore the essential factors to consider when selecting an inspection robot, enabling industries to harness the full potential of this innovative technology in their pursuit of operational excellence.

Identify Your Industry-Specific Inspection Requirements

Selecting the right inspection robot demands a clear understanding of the specific requirements unique to your industry. For instance, in the manufacturing sector, robots typically need to perform real-time quality assessments to ensure compliance with industry standards, such as ISO 9001. According to a report by MarketsandMarkets, the global quality inspection market is expected to reach $20.7 billion by 2025, emphasizing the growing need for tailored inspection capabilities within manufacturing processes. By identifying specific roles—such as defect detection, dimensional inspection, or surface analysis—companies can leverage robotic solutions that minimize human error and enhance operational efficiency.

In sectors like oil and gas, inspection requirements can differ significantly due to the hazardous environments and complex infrastructure involved. Robotics for pipeline inspection must meet stringent safety regulations and provide high-resolution imaging and defect analysis to detect corrosion, leaks, or structural failures. A report by Grand View Research indicates that the inspection drones market in oil and gas is projected to grow at a CAGR of 15.6% from 2021 to 2028, showcasing the rising importance of industry-specific technology capable of addressing safety and regulatory challenges. Understanding these unique demands will guide companies in selecting the most appropriate inspection robots, ensuring not only compliance but also optimal performance across various operational contexts.

Inspection Robot Features by Industry

This bar chart illustrates the various features prioritized by different industries when selecting inspection robots, highlighting the specific needs across sectors.

Evaluate Key Features of Inspection Robots

When selecting the right inspection robot for your industry needs, it's crucial to evaluate several key features that can significantly impact operational efficiency and effectiveness. According to a recent report from MarketsandMarkets, the inspection drone market alone is projected to reach $12 billion by 2025, highlighting the increasing reliance on advanced robotics in quality control processes. Features such as mobility, sensor technology, and data analysis capabilities are essential. For instance, a robot equipped with high-definition cameras and thermal sensors can detect discrepancies in asset conditions that might go unnoticed in human inspections.

Furthermore, interoperability is a significant factor to consider. A robust inspection robot should seamlessly integrate with existing monitoring systems to streamline workflows. A study published by ResearchAndMarkets indicates that 70% of organizations seek automation solutions that support real-time data sharing to enhance decision-making processes. Moreover, battery life and charging capabilities are critical for ensuring optimal performance in various environments. Businesses must assess their operational requirements and choose robots that not only meet current demands but can also adapt to evolving industry needs. By focusing on these key features, organizations can invest in inspection robots that drive productivity and accuracy in their quality assurance processes.

How to Choose the Right Inspection Robot for Your Industry Needs - Evaluate Key Features of Inspection Robots

| Feature | Description | Importance Level | Typical Industries |

|---|---|---|---|

| Mobility | The ability to navigate different terrains and environments. | High | Manufacturing, Oil & Gas, Construction |

| Camera Quality | Resolution and features of the cameras on the robot. | High | Inspection, Surveillance, Security |

| Payload Capacity | The maximum weight the robot can carry. | Medium | Logistics, Warehouse Operations |

| Battery Life | Duration the robot can operate before needing a recharge. | High | Field Operations, Agriculture |

| Data Processing | The ability to analyze and interpret data in real-time. | High | Manufacturing, Inspections |

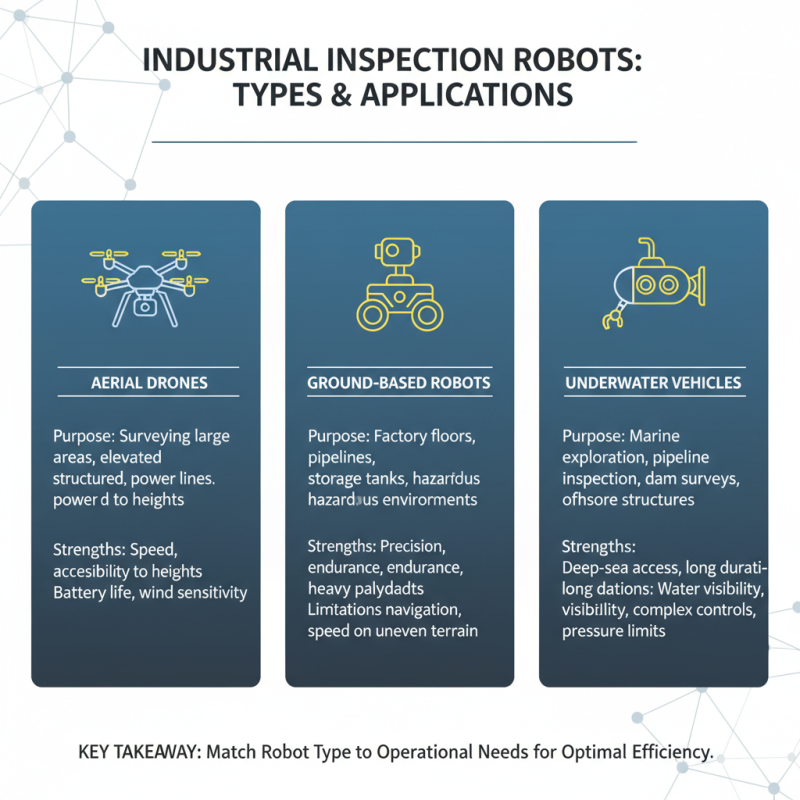

Compare Different Types of Inspection Robots Available

When selecting an inspection robot for your industry, it's crucial to understand the different types available and their suitability for specific applications. Inspection robots can generally be categorized into several types, including aerial drones, ground-based robots, and underwater vehicles. Each type serves distinct purposes: aerial drones excel in surveying large areas from above, ground-based robots are perfect for factory inspections, and underwater robots are designed for marine explorations. Knowing the strengths and limitations of each type is essential in aligning robot capabilities with operational needs.

Tips: Before making a decision, consider the environment where the robot will operate. For example, if you're conducting inspections in confined spaces, a smaller, agile ground robot may be most effective. Conversely, if your inspections require monitoring from a height or covering large, inaccessible areas, an aerial drone would be the better choice. Additionally, think about the robot's payload capacity; ensure it can carry any necessary sensors or cameras to perform its tasks efficiently.

Another important comparison factor is the autonomy level of the robots. Some models offer teleoperated functionality, while others are fully autonomous, using advanced algorithms and sensors to navigate and perform tasks. If your operations demand continuous inspections without human intervention, investing in an autonomous robot could enhance efficiency and reduce labor costs. Consider these aspects carefully when comparing different inspection robots to ensure you choose the best fit for your specific industry requirements.

Assess Budget Considerations for Robot Selection

When selecting an inspection robot tailored for your industry needs, budget considerations play a crucial role in ensuring that your investment meets both operational requirements and financial constraints.

To effectively assess your budget, begin by determining the essential features your inspection robot must possess. This involves evaluating the specific tasks it needs to perform, such as detecting structural issues in construction or monitoring product quality in manufacturing.

By outlining these necessities, you can establish a budget range that aligns with your operational goals.

Tips: Consider not only the initial purchase price but also ongoing maintenance and software upgrade costs. Understanding the total cost of ownership will provide a clearer financial picture and help you avoid surprising expenses down the line.

Additionally, explore financing options or leasing agreements if upfront costs are a concern, allowing for flexibility in managing your budget.

Furthermore, it’s essential to analyze potential ROI from deploying the inspection robot. Estimate the cost savings from increased efficiency, reduced downtime, and enhanced compliance.

These factors will allow you to justify a higher initial investment if the long-term benefits are evident. By taking a strategic approach to budgeting, you can choose an inspection robot that not only fits your financial plans but also enhances your operational capabilities.

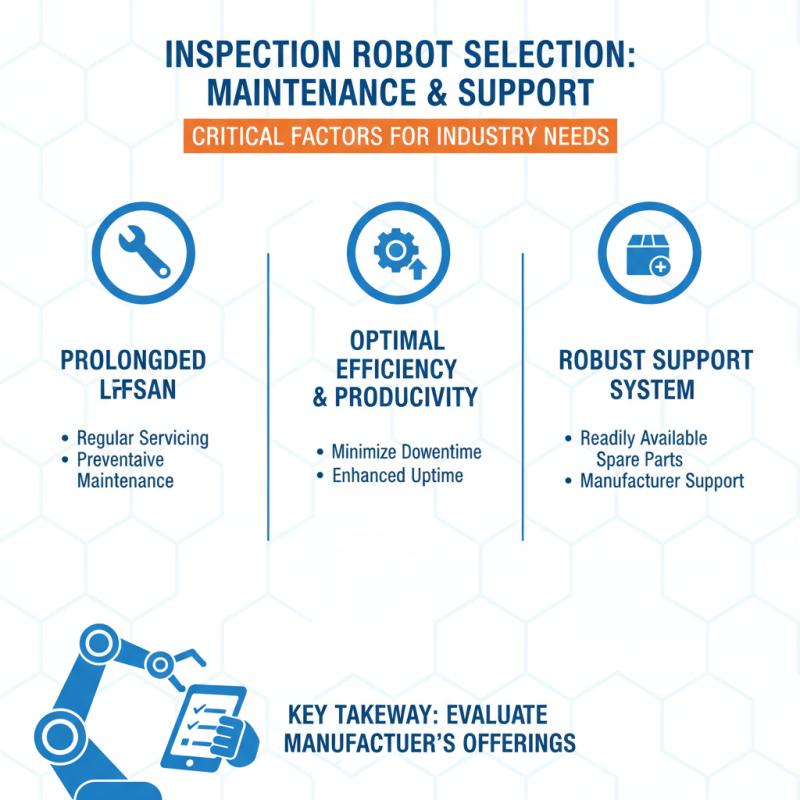

Review Maintenance and Support Options for Chosen Robots

When selecting the right inspection robot for your industry needs, one of the most critical factors to consider is the maintenance and support options available for the chosen technology. Comprehensive maintenance programs can prolong the life of the robot, ensuring that it operates at peak efficiency. It’s essential to evaluate whether the manufacturer offers regular servicing, preventive maintenance, and readily available spare parts. A robust support system contributes to minimizing downtime and enhancing productivity in high-stakes environments.

Furthermore, look for training and warranty options that are part of the support package. A good training program ensures that your team is well-versed in operating and troubleshooting the robot, which can significantly reduce reliance on external help. Additionally, a solid warranty can provide peace of mind, protecting your investment and allowing for easier budgeting for long-term upkeep. Understanding these aspects will enable you to make a well-rounded decision and ensure that your inspection robot meets not only immediate operational demands but also future maintenance requirements.

Related Posts

-

Revolutionizing Industries: How Robot Vision Systems Enhance Automation and Efficiency

-

10 Essential Tips for Servo Robot Seam Tracking Success

-

2025 Guide: How to Optimize Robotic Arc Welding for Maximum Efficiency

-

How to Master Robotic Arc Welding: Tips, Techniques, and Best Practices

-

Exploring the Future of Robotic Process Automation for Business Efficiency

-

Exploring the Future of Robot Servo Technology at the 2025 China Import and Export Fair