How to Choose the Best Robot Vision System for Your Business Needs

In today’s rapidly evolving industrial landscape, the integration of technology has become imperative for businesses aiming to enhance efficiency and productivity. Among the innovations reshaping various sectors, the robot vision system stands out as a critical tool that enables automation and precision in operations. By mimicking human sight, these sophisticated systems provide robots with the ability to perceive their environment, making informed decisions based on visual data. As companies consider the adoption of a robot vision system, it is essential to evaluate their specific needs, objectives, and the potential impact on their workflow.

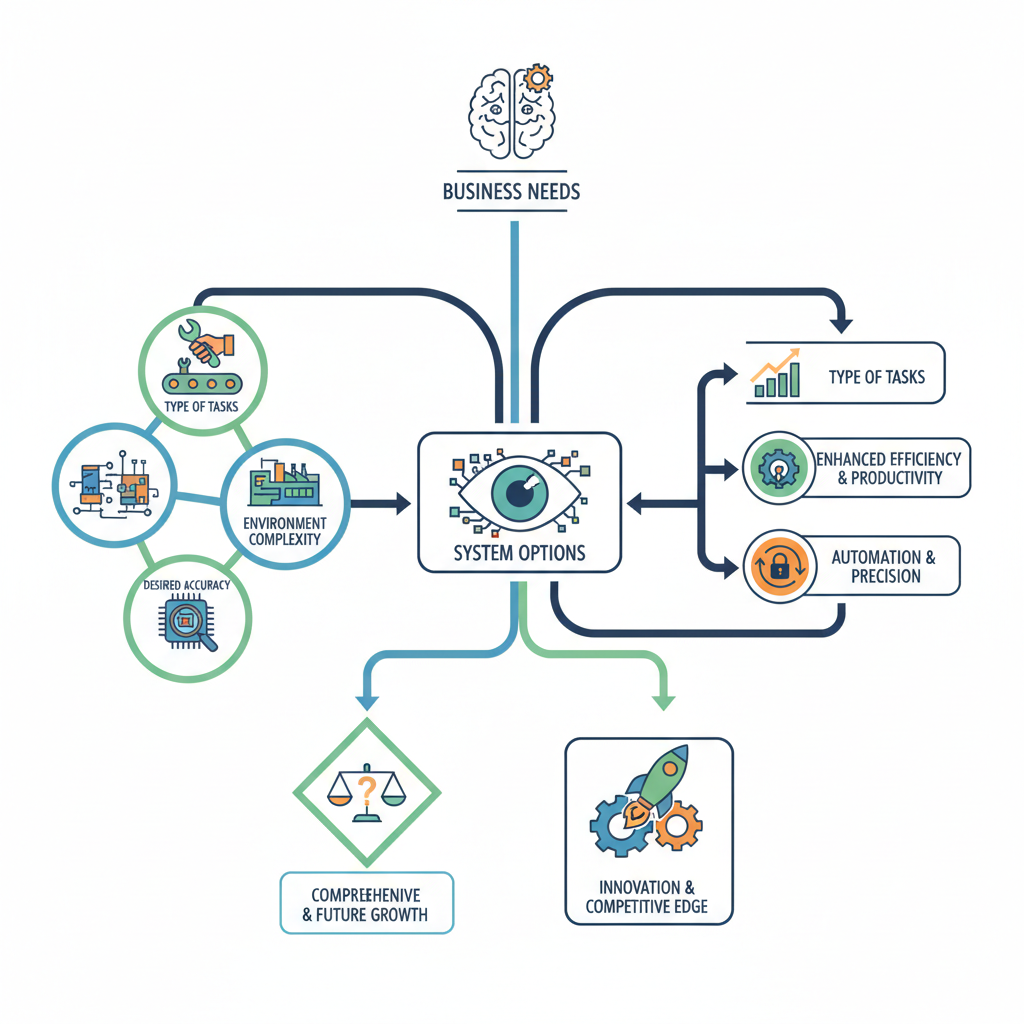

Choosing the right robot vision system requires a comprehensive understanding of the various options available and how they align with the company’s operational goals. Factors such as the type of tasks, the complexity of the environment, and the desired level of accuracy play crucial roles in this decision-making process. Consequently, businesses must conduct a thorough analysis to identify the most suitable solution that not only meets their requirements but also offers scalability for future growth. By making an informed choice, companies can harness the full potential of robot vision technology, driving innovation and maintaining a competitive edge in their respective industries.

Understanding the Basics of Robot Vision Systems

Robot vision systems are rapidly transforming industries by enabling machines to interpret visual information from their surroundings. Understanding the basics of these systems is essential for businesses looking to leverage automation technology effectively. At their core, robot vision systems utilize cameras and advanced algorithms to capture and analyze images, allowing robots to perform tasks such as quality inspection, object detection, and navigation. With the rise of smart factories, machine vision has become a critical component for enhancing production efficiency and ensuring operational excellence.

As companies increasingly adopt AI-driven technologies, incorporating robust robot vision systems can significantly improve workflow and accuracy. These systems can adapt to various environments and tasks through sophisticated feedback mechanisms, facilitating greater flexibility in manufacturing processes. Additionally, the integration of machine vision with artificial intelligence is paving the way for more intelligent automation solutions that not only streamline operations but also contribute to better decision-making. Understanding these fundamentals can help businesses choose the right robot vision system tailored to their unique needs and objectives.

How to Choose the Best Robot Vision System for Your Business Needs

| Feature | Description | Importance Level |

|---|---|---|

| Image Resolution | The clarity of images captured, affecting detection accuracy. | High |

| Processing Speed | How quickly the system can analyze and interpret images. | Medium |

| Lighting Conditions | Ability to function under varying light conditions. | High |

| Field of View | The extent of the observable area captured. | Medium |

| Integration Capabilities | How well the system can work with existing equipment. | High |

| Cost | Total investment required, affects budget decisions. | High |

| Support & Maintenance | Availability of technical support and maintenance services. | Medium |

| Software Flexibility | Ease of adapting or updating the software for new tasks. | Medium |

Identifying Your Business Needs for Vision Technology

When considering a robot vision system, the first step is to clearly identify your business needs and objectives. Start by evaluating the specific tasks you want the robotic system to perform. For instance, are you looking for quality inspection, sorting, or assembly automation? Understanding the primary functions will help narrow down the technology options and ensure that the chosen system aligns with your operational goals.

Next, assess the environment in which the robot vision system will operate. Factors such as lighting conditions, workspace dimensions, and the type of materials being handled can significantly influence performance. For example, if your business operates in a high-variability environment, choose systems equipped with adaptive lighting and robust algorithms. By comprehensively addressing these needs, you can make a more informed decision, leading to increased efficiency and productivity within your operations.

Robot Vision System Features Comparison

This bar chart displays a comparison of key features for evaluating robot vision systems. Each rating represents the system's effectiveness, with higher values indicating better performance regarding image resolution, processing speed, object recognition, integration ease, and cost considerations.

Comparing Different Types of Robot Vision Systems

When selecting a robot vision system, it's crucial to understand the various types available, as each has distinct capabilities that cater to different business needs.

One of the most common categories is 2D vision systems, which use cameras and imaging software to analyze flat surfaces.

These systems excel in applications requiring precise measurements and quality control, making them ideal for manufacturing processes that involve inspection and sorting.

On the other hand,

3D vision systems offer a more advanced approach by capturing depth information, allowing robots to perceive their environment in a more nuanced way.

This type is particularly beneficial for tasks that involve navigating complex environments or handling irregularly shaped objects.

By employing technologies like laser scanning or stereo cameras, 3D vision systems can enhance automation in logistics, assembly, and robotic picking operations, providing a competitive edge in environments that demand flexibility and precision.

Evaluating Key Features and Specifications

When selecting the best robot vision system for your business, evaluating key features and specifications is crucial. One of the primary factors to consider is the resolution of the camera. According to a recent report from MarketsandMarkets, the industrial camera market is projected to grow to $4.6 billion by 2025, driven largely by advancements in camera technology that increase image resolution and processing speed. Higher resolution cameras not only improve the accuracy of visual inspections but also enhance the flexibility of applications across various industries.

Another essential specification to evaluate is the processing capability of the vision system. High-performance vision systems equipped with advanced algorithms can analyze images in real-time, significantly improving operational efficiency. A study conducted by the Association for Advancing Automation (A3) highlights that companies using AI-powered vision systems experience a 20-30% increase in productivity. Additionally, consider the integration capabilities of the vision system with existing automation platforms, as compatibility can streamline workflows and minimize operational disruptions, enabling seamless deployment in your production environment.

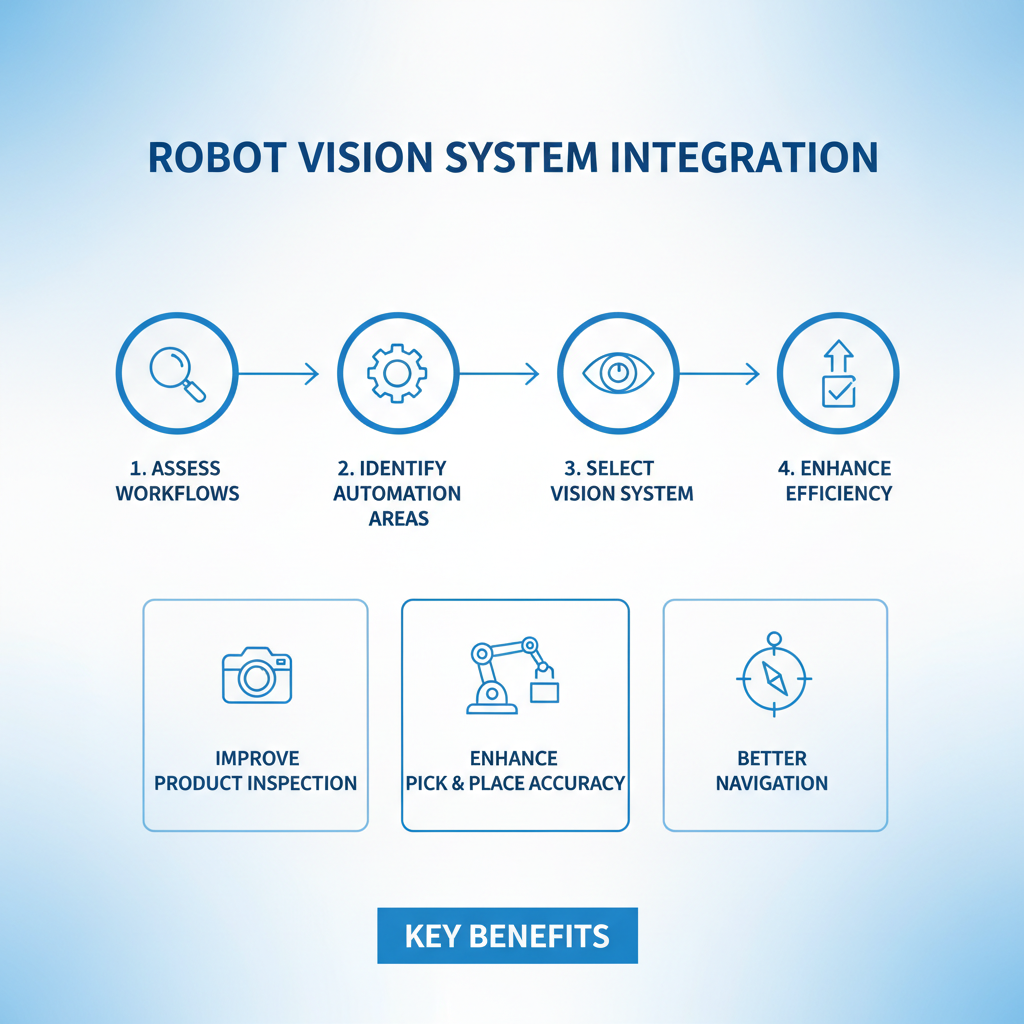

Integrating Robot Vision Systems into Existing Operations

Integrating robot vision systems into existing operations requires a careful assessment of both the technological capabilities and the specific needs of your business. The first step is to evaluate your current workflows and identify areas where automation could enhance efficiency. This analysis helps in selecting a robot vision system that addresses your most pressing challenges, such as improving product inspection, enhancing accuracy in picking and placing, or enabling better navigation in dynamic environments.

Once you have identified the potential applications, it's essential to ensure that the robot vision system can seamlessly integrate with your current machinery and software infrastructures. This may involve upgrading existing hardware or utilizing middleware that allows different systems to communicate effectively. Partnering with experienced vendors can provide insights into compatibility and integration processes, ensuring that the new technology aligns with your operational objectives. Proper training for staff will also facilitate a smoother transition and optimize the performance of the new system in the long run.

Related Posts

-

Top 10 Amazing Innovations in Robot Vision Technology You Need to Know

-

Exploring the Future of Robotic Vision: Innovations That Transform Industries

-

Revolutionizing Industries: How Robot Vision Systems Enhance Automation and Efficiency

-

What is Robotic Vision? Understanding Its Importance and Applications in Automation

-

2025 How to Enhance Robotic Performance with 3D Vision Systems in Automation

-

Robotic Process Innovations at the 138th Canton Fair 2025 Transforming Industry Standards in China