Why Are 3D Robots Revolutionizing Industries Today?

The rise of 3D robots is transforming various industries today. Experts agree on their potential. Dr. Emily Carter, a leader in robotics research, noted, "3D robots bring efficiency and creativity together." Industries are embracing these machines for rapid prototyping, customized manufacturing, and even intricate designs.

In construction, 3D robots can create structures layer by layer. They reduce waste and speed up the building process. Similarly, in healthcare, these robots produce patient-specific implants with precision. This creates a new frontier in medical technology.

Yet, challenges remain. The cost of advanced 3D robots can be high. Not all companies can easily adopt this technology. There is also a learning curve that cannot be overlooked. As we explore this revolution, a balance between innovation and practicality is crucial.

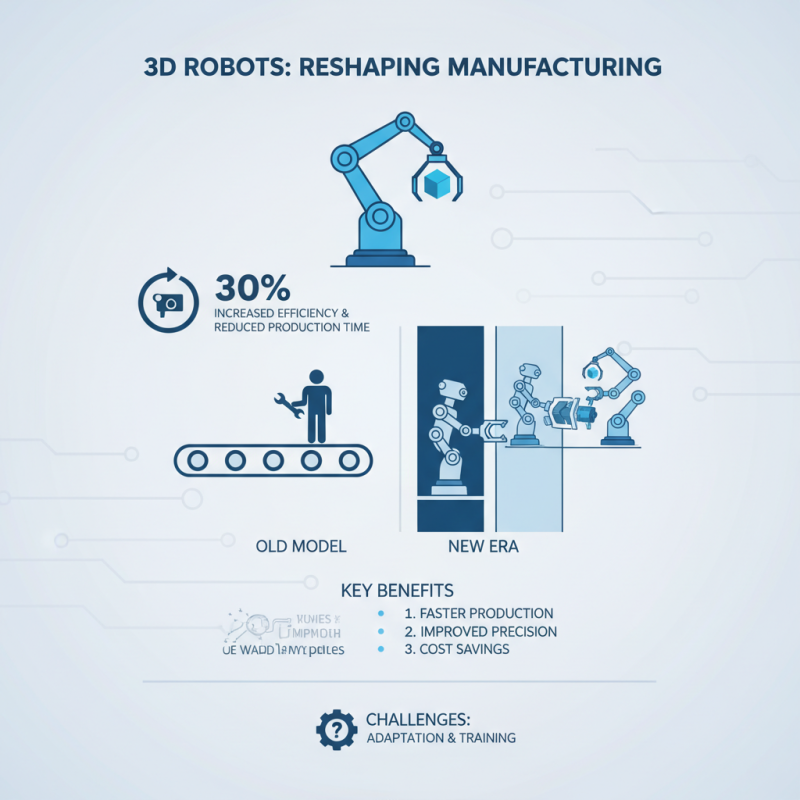

The Emergence of 3D Robots in Manufacturing: Key Statistics and Trends

The rise of 3D robots in manufacturing is changing how industries operate. These robots are not just tools; they are reshaping production lines. Reports show that 3D robots can significantly cut production time. In some cases, companies report up to a 30% increase in efficiency. Yet, this rapid evolution raises challenges.

Training workers to collaborate with robots is vital. Many employees feel overwhelmed. They need to adapt to new technologies quickly. The statistics are clear: firms that invest in worker training see better results. However, there are still gaps in understanding how to effectively integrate these robots.

Interestingly, 3D robots also create new possibilities. They can produce complex designs that traditional methods cannot achieve. Some industries report a decrease in waste by up to 25%. Yet, the environmental impact of widespread robotics requires careful consideration. There are still questions about sustainability and ethical production. Balancing innovation with responsibility is a pressing concern for the future.

Impact of 3D Robotics on Supply Chain Efficiency and Cost Reduction

3D robotics is changing how industries operate. These robots streamline supply chain processes, leading to remarkable efficiency gains. They automate tasks that were once manual, reducing the possibility of human errors. This shift not only enhances productivity but also decreases operational costs significantly.

In warehouses, 3D robots navigate intricate layouts. They pick and sort items swiftly. Yet, challenges remain. Integrating these systems into existing operations can be complex. Some workers may feel threatened by automation's rise. This tension can create an atmosphere of uncertainty. Balancing human roles with robotic efficiency is crucial for future success.

Cost reduction is another critical area impacted by 3D robotics. Companies can lower their labor expenses while maintaining high output levels. Despite the benefits, investment in these technologies requires careful consideration. Will the initial outlay outweigh the long-term savings? It’s a question every business must face as they embrace this technological revolution.

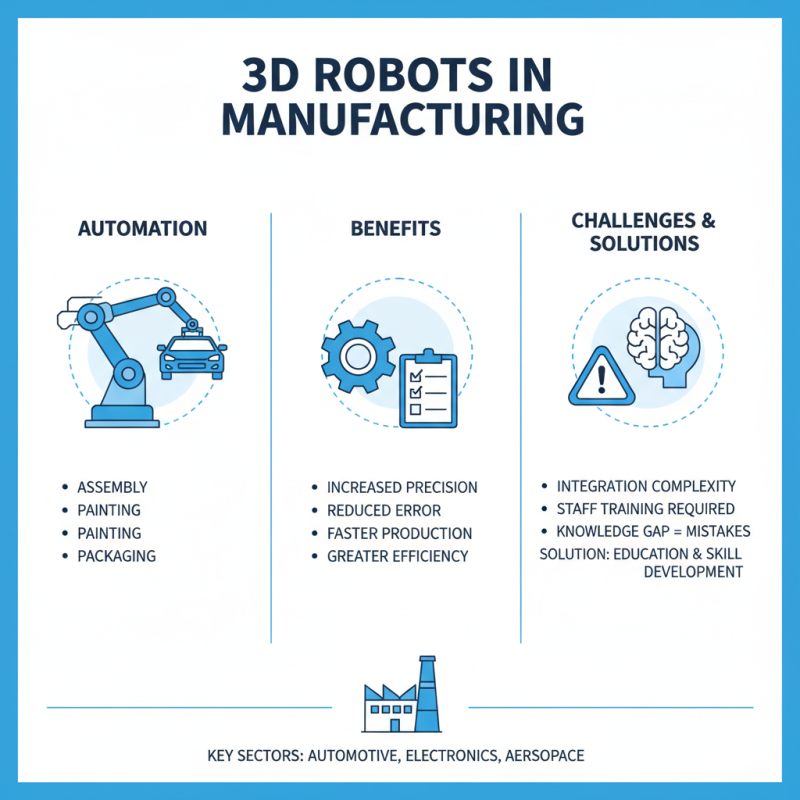

Case Studies: Industries Transforming with 3D Robots in Production

In the manufacturing sector, 3D robots are making waves. They automate tasks like assembling, painting, and packaging. For example, in automotive production, these robots create precise parts quickly. They minimize human error and increase efficiency. However, integrating 3D robots can be challenging. Training staff is essential. Without proper knowledge, mistakes can happen.

Another industry seeing transformation is healthcare. 3D robots assist in surgeries, providing higher accuracy. They can replicate delicate movements. This reduces recovery time for patients. Yet, reliance on technology raises questions. What if a robot malfunctions? Human oversight remains crucial. Careful planning and protocols must be in place.

Food production is also evolving with 3D robots. They streamline processes, from sorting to packaging. This ensures consistency in products. Challenges arise with food safety standards. Facilities must adapt to meet regulations. Balancing technology and safety presents a constant challenge for businesses.

Future Projections: Market Growth and Advancements in 3D Robotics

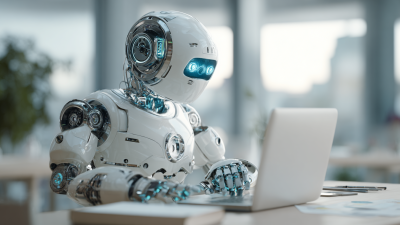

The field of 3D robotics is experiencing rapid growth. Industries are integrating these robots into their operations. The market is projected to expand significantly in the coming years. Research indicates a strong demand for automation. In manufacturing, 3D robots enhance precision and efficiency. They reduce waste and increase productivity. However, challenges remain. The technology must keep evolving to meet diverse needs.

Advancements in materials and AI are key drivers. Stronger, lighter materials enable more versatile designs. AI enhances the robots' ability to adapt to various tasks. Yet, the high costs can limit accessibility. Smaller companies might struggle to invest in these advancements. There is also concern about job displacement. While robots can perform many tasks, human oversight remains crucial.

Future projections suggest that collaboration between humans and robots can lead to optimal results. This partnership could define the next era of industry. However, ensuring ethical practices will be vital. Balancing innovation with responsibility presents a challenge for all stakeholders involved. The promise of 3D robotics is immense, but it requires careful navigation.

Integration Challenges: Overcoming Barriers to 3D Robot Adoption in Industries

Integrating 3D robots into industries presents significant challenges. Many companies face technical difficulties when adapting existing workflows. Employees often require retraining, which may slow down the process. Undertaking such a transition can be costly and time-consuming. Equipment compatibility is another major concern. Not all machines are ready to communicate with automated systems.

Despite these barriers, some organizations are finding creative solutions. They focus on gradual implementation rather than a complete overhaul. This approach allows for adjustments along the way. Collaboration between teams is critical in overcoming obstacles. Communication helps ensure everyone is on the same page. Employees may feel apprehensive about using new technology, which can hinder progress.

Moreover, organizations must address the long-term impacts of these changes. Regular assessments can help identify what works and what doesn't. Keeping track of metrics is essential for refining processes. Companies must acknowledge that the path to integration is not always smooth. Reflecting on missteps can lead to better strategies. Embracing a culture of adaptation can promote innovation in the face of uncertainty.

Bar Chart: Challenges in 3D Robot Adoption Across Industries

Related Posts

-

Top 10 Tips for Choosing the Right Inspection Robot for Your Industry

-

Exploring the Future of Robotic Laser Welding in Advanced Manufacturing Techniques

-

Revolutionizing Fabrication: The Future of Seam Tracking Welding Technology Explained

-

2026 How to Choose the Best Welding Robot for Your Business Needs?

-

Why Robot Software is Essential for Modern Business Efficiency

-

Top 5 Benefits of Robotic Process Automation for Modern Businesses