Why is 3D Robot Vision Essential for Advanced Automation?

The integration of 3D robot vision is vital for modern automation. With the manufacturing sector evolving rapidly, advanced automation is necessary for efficiency and precision. Reports indicate that industries implementing robotic vision systems can achieve up to a 35% increase in production efficiency. According to Dr. Allen Thompson, a renowned expert in robotic systems, "3D robot vision transforms the way machines interact with their environment." This technology empowers robots to assess their surroundings in real-time, enabling complex tasks that were once impractical.

However, despite the clear advantages, the adoption of 3D robot vision isn't without challenges. Many manufacturers struggle with high initial costs and the complexity of integrating these systems. The return on investment can be uncertain, making businesses hesitant. Companies must reflect on their long-term goals when considering these technologies. Assessing not just immediate benefits but also potential setbacks is crucial.

As we move deeper into an era of smart manufacturing, the role of 3D robot vision will only grow. Companies willing to face the challenges could gain a significant competitive edge. The future of automation hinges on how effectively industries leverage these advanced visual systems.

The Role of 3D Robot Vision in Enhancing Automation Efficiency

The integration of 3D robot vision is transforming automation. This technology enhances operational efficiency drastically. According to a recent industry report, companies implementing 3D vision systems report a 30% increase in productivity. This rise comes from reduced errors in tasks such as assembly and quality inspection. Traditional 2D systems often miss critical depth information. This shortcoming can result in costly mistakes.

3D vision allows robots to perceive their environment in three dimensions. This capability is essential for navigating complex spaces. In warehouses, robots equipped with 3D vision can identify objects with irregular shapes. They adapt to varying conditions swiftly. However, implementing this technology can be challenging. The calibration of 3D systems requires expertise. A failure in calibration can lead to significant operational downtime.

Tip: Invest in training for staff on the nuances of 3D vision technology. Encouraging a culture of continuous learning can mitigate the learning curve associated with new systems. Keep abreast of the latest advancements to remain competitive.

Understanding the potential flaws in 3D vision is crucial. Factors like lighting and reflections can affect accuracy. Regularly test and recalibrate systems to ensure optimal performance. As technology evolves, so must our approaches to automation.

Key Benefits of 3D Robot Vision for Manufacturing Processes

3D robot vision is reshaping the manufacturing landscape. It provides machines with the ability to perceive depth and distance, which enhances their automation capabilities. According to a report by the International Federation of Robotics, firms using 3D vision systems can increase productivity by up to 30%. This technology allows for precise picking and placing, making robotic systems more effective.

The integration of 3D vision minimizes errors in production. Robots can identify and adjust to varying shapes and sizes of products. A study by McKinsey indicates that automation combined with advanced vision systems reduces defects by up to 40%. It's essential to understand that transitioning to such technology may not always be straightforward. Implementation can require significant time and investment in training.

Despite the challenges, the benefits of enhanced efficiency and quality are compelling. Warehouse environments often vary greatly, complicating tasks. Yet, 3D robot vision systems adapt well when tailored correctly. This adaptability proves vital in today’s rapidly changing manufacturing frameworks, where precision is paramount. Robotics is evolving, but perfection is still a journey.

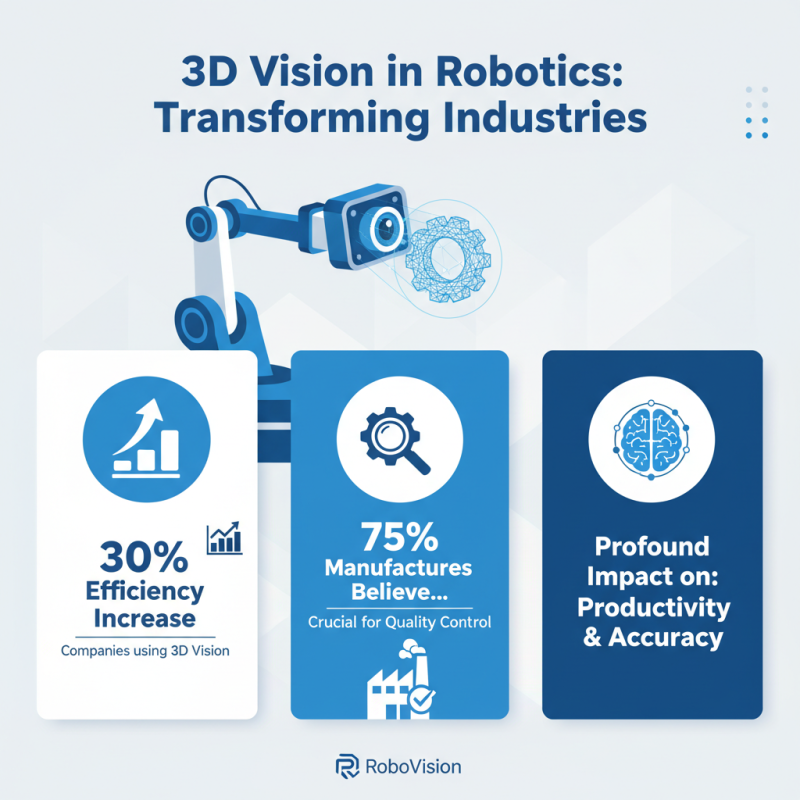

Industry Statistics on the Impact of 3D Vision in Robotics

The use of 3D vision in robotics is significantly transforming industries. According to recent statistics, companies using 3D vision technology have reported a 30% increase in efficiency. Another study revealed that 75% of manufacturers believe 3D vision is crucial for quality control in automation. These numbers illustrate a profound impact on productivity and accuracy.

Integrating 3D vision helps robots recognize and manipulate objects with precision. The ability to gauge depth allows for improved navigation in complex environments. However, implementing this technology isn't without challenges. Cost and technical expertise are barriers many small businesses face. Some 3D vision systems can be expensive or require extensive training to operate effectively.

Tip: Start small. Assess your current processes and identify areas where 3D vision could make an impact. Testing with a pilot program can help reduce risks. It’s important to learn from setbacks during this process. Continuous training and adaptation are key to harnessing the full potential of this technology. Investing in the right systems can lead to an impressive return, but it is essential to stay realistic about expectations.

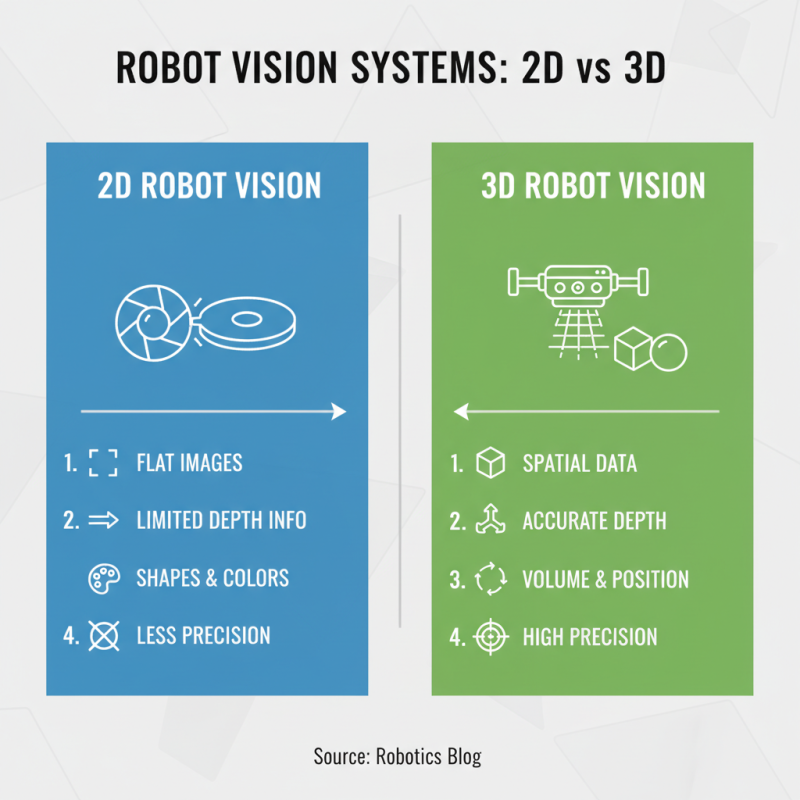

Comparative Analysis of 2D vs. 3D Robot Vision Technologies

In the realm of robotics, vision systems play a pivotal role. Comparing 2D and 3D technologies reveals notable differences. 2D robot vision uses flat images, providing limited information. It recognizes shapes and colors but struggles with depth perception. This lack of dimensional awareness can hinder tasks requiring precision.

On the other hand, 3D robot vision offers much more depth. These systems use various sensors to create three-dimensional maps of environments. They can detect distance and volume, which is vital for intricate assembly tasks. However, 3D systems can be more complex to implement. They often require advanced processing capabilities. Installation may also demand significant time and resources.

There are elements to consider in both technologies. While 2D systems are simpler, they can be inadequate for many applications. The transition to 3D may present challenges, yet the benefits are clear. Poor integration can lead to errors or slow performance. Striking the right balance is essential for achieving efficient automation.

Future Trends: The Evolution of 3D Vision in Automation Systems

The evolution of 3D vision in automation systems is fascinating. As technology progresses, 3D robot vision becomes increasingly crucial. Robots can now understand their environment better. This capability boosts efficiency and accuracy in various industries.

Trends indicate a shift towards more sophisticated sensors. These sensors gather rich data about objects. Robots can now identify shapes, sizes, and distances with precision. However, integrating these systems isn't always straightforward. Some setups may struggle with complex environments. This complexity requires ongoing adjustments and monitoring.

Tips: Always test different sensor placements. Small changes can yield significant improvements. Also, ensure proper lighting conditions for the sensors to perform optimally. A well-lit workspace can enhance vision accuracy.

Future advancements will likely focus on AI integration. AI can analyze data in real time, enhancing decision-making. Nevertheless, this technology may come with challenges. Compatibility issues between systems may arise. Organizations need to plan for flexibility and adaptability in their automation strategies. Exploring these aspects will be essential for success.

Impact of 3D Robot Vision on Automation Efficiency

This chart illustrates the percentage increase in automation efficiency across various industries with the integration of 3D robot vision technology over the last five years. The data highlights the significant improvement in productivity and quality control achieved in manufacturing, logistics, and healthcare sectors.

Related Posts

-

How to Enhance Your Photography Skills with Innovative Camera Robots

-

How to Leverage Robotic Vision for Enhanced Automation in 2025

-

Top Camera Robots for Photography and Filmmaking Innovations?

-

Why Do Robots Need 3D Vision Systems for Enhanced Navigation and Interaction?

-

Exploring the Future of Robotic Process Automation for Business Efficiency

-

Top Robotic Vision Technologies Transforming Industries Today