2025 Guide: How to Optimize Robotic Arc Welding for Maximum Efficiency

In the fast-evolving landscape of manufacturing, robotic arc welding has emerged as a pivotal technology, driving efficiency and precision in fabrication processes. As industries increasingly demand higher productivity and quality, optimizing robotic arc welding systems becomes essential for companies striving to stay competitive. This guide aims to provide insights and strategies to enhance the efficiency of robotic arc welding operations, empowering manufacturers to achieve optimal performance and reduced operational costs.

The significance of robotic arc welding lies not only in its ability to automate complex welding tasks but also in its potential to improve overall production timelines. Understanding the key factors that influence the efficiency of robotic arc welding, such as equipment calibration, programming techniques, and workflow integration, is crucial for maximizing the benefits of this technology. Whether you are a seasoned expert or new to robotic systems, this guide offers a comprehensive framework to help you unlock the full potential of robotic arc welding in your manufacturing processes. By implementing best practices and staying attuned to technological advancements, businesses can ensure their operations are both effective and future-ready.

Understanding Robotic Arc Welding and Its Importance in Industry

Robotic arc welding has emerged as a cornerstone of modern manufacturing, crucial for enhancing productivity and ensuring high-quality outputs across various industries. According to a 2021 report by the International Federation of Robotics, robotic automation in welding operations saw an annual growth rate of over 15%, reflecting its increasing importance in sectors such as automotive, aerospace, and construction. The precision and repeatability offered by robotic systems minimize errors and reduce material waste, significantly improving the overall efficiency of production processes.

To optimize robotic arc welding, understanding the specific parameters that affect performance is key. Factors such as welding speed, electrode position, and power settings must be carefully calibrated to match material types and thicknesses. For instance, maintaining an optimal welding speed can lead to a reduction in heat-affected zones, which not only preserves material integrity but also enhances joint strength.

Tips for Optimization: Regular maintenance of the robotic systems is vital to ensure consistent performance. Scheduled inspections help in identifying wear and tear before they lead to significant downtime. Additionally, continuous training for operators can further enhance productivity by ensuring that all personnel are proficient in troubleshooting and adjusting welding parameters as needed. By focusing on these factors, industries can harness the full potential of robotic arc welding, driving efficiencies that set them apart in a competitive market.

2025 Guide: How to Optimize Robotic Arc Welding for Maximum Efficiency

| Parameter | Value | Importance |

|---|---|---|

| Welding Speed (m/min) | 2.5 | Optimizing speed enhances productivity. |

| Heat Input (kJ/mm) | 1.2 | Control heat for better weld quality. |

| Robot Utilization Rate (%) | 85 | Higher rates reduce idle time. |

| Material Thickness (mm) | 5.0 | Affects the choice of welding parameters. |

| Preheat Temperature (°C) | 150 | Preheating minimizes thermal shock. |

| Welding Wire Diameter (mm) | 1.2 | Diameter influences feed rate and penetration. |

| Shielding Gas Type | Argon/CO2 Mixture | Gas mixture affects bead appearance and penetration. |

| Post-Weld Inspection Method | Ultrasonic Testing | Ensures weld integrity and quality. |

Key Components of Robotic Arc Welding Systems for Optimal Performance

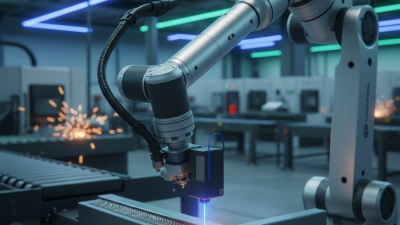

Robotic arc welding has become a cornerstone in manufacturing, driven by the need for precision and efficiency. Understanding the key components of robotic arc welding systems can significantly enhance performance. Firstly, the robot's manipulator and welding torch are crucial; their design must accommodate the specific geometry of the parts being welded. According to the International Federation of Robotics, integrating advanced sensors enhances the adaptability of these systems, allowing for real-time adjustments and improved weld quality.

Utilizing a high-performance power source is another vital aspect. A power source must provide consistent voltage and current, which are essential for achieving optimal welding characteristics. Industry reports indicate that systems with inverter technology can increase efficiency by up to 30% compared to traditional systems. Additionally, the choice of filler material plays an important role in the overall weld quality and durability, so selecting the correct type based on the application is critical.

**Tips:** To maximize efficiency, regularly calibrate and maintain your robotic welding equipment. Implementing a preventive maintenance schedule helps to identify potential issues before they become costly repairs. Furthermore, training staff on the latest welding technologies and techniques can lead to improved productivity and product turnaround times. Lastly, consider investing in software that can simulate welding operations to optimize programming and minimize errors before actual production.

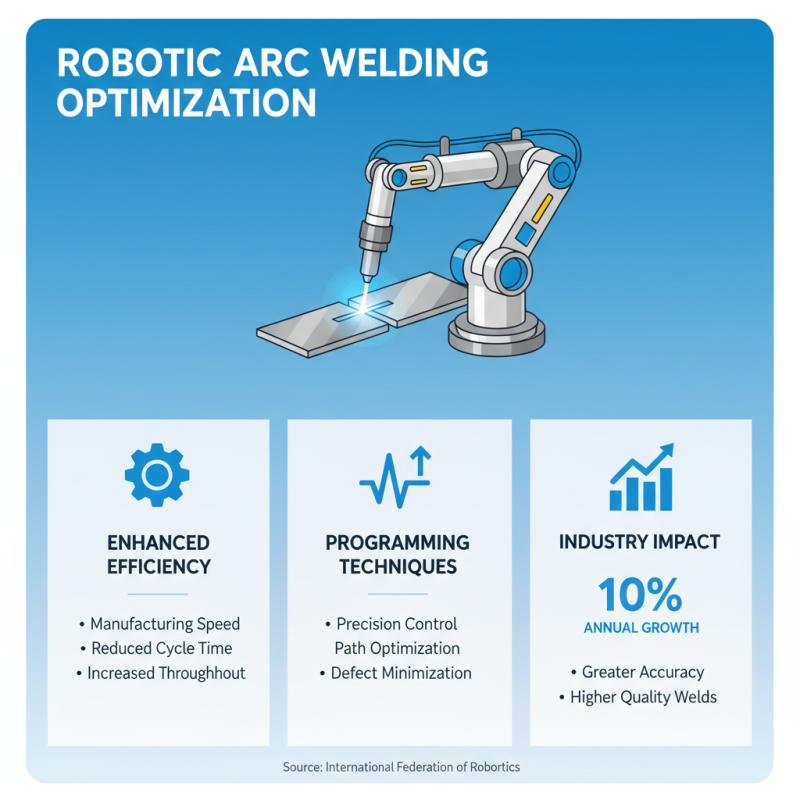

Robotic Arc Welding Efficiency Optimization Factors

Techniques for Programming Robots for Enhanced Welding Precision

The optimization of robotic arc welding is pivotal in enhancing manufacturing efficiency, and programming techniques play a crucial role in achieving this goal. According to a report from the International Federation of Robotics, the demand for automated welding solutions is projected to grow by 10% annually, fueled by industries aiming for greater precision and reduced costs. Accurate programming of robotic arms not only enhances the quality of welds but also minimizes defects, thus increasing overall production output.

One effective technique for improving welding precision involves utilizing advanced simulations before execution. By implementing computer-aided design (CAD) and robotic simulation software, manufacturers can pre-emptively identify potential issues in the welding path and adjust settings accordingly. A study from the American Welding Society indicates that such simulation tools can improve welding consistency by up to 30%, which significantly decreases the time spent on reworks and enhances operator safety. Furthermore, integrating machine learning algorithms into programming can allow robots to learn from previous welding processes, adapting in real-time to optimize parameters like travel speed and electrode angle for varying materials. This adaptive capability is expected to further elevate productivity levels in precision-intensive tasks.

Strategies for Maintaining and Upgrading Welding Equipment Efficiency

Maintaining and upgrading welding equipment is crucial for optimizing robotic arc welding processes and achieving maximum efficiency. Regular maintenance ensures that components are functioning correctly, which directly impacts the quality of welds and the overall productivity of the operation. Implementing a maintenance schedule that includes routine checks of the welding torch, power source, and robotic arm can prevent unexpected downtime. Additionally, using high-quality consumables and lubricants can extend the life of equipment and reduce the frequency of repairs.

Upgrading welding equipment with the latest technologies is another effective strategy to enhance efficiency. Incorporating advanced sensors and software can facilitate real-time monitoring and adjustments during the welding process, ensuring optimal performance. Moreover, investing in automation tools, such as adaptive welding systems, can improve precision and reduce waste. Training personnel on new equipment and techniques will further maximize the benefits of these upgrades and ensure that the workforce is adept at leveraging technology for enhanced productivity. In essence, a combination of diligent maintenance and timely upgrades forms the foundation for maintaining high operational efficiency in robotic arc welding applications.

Analyzing Data and Metrics to Improve Robotic Welding Productivity

To optimize robotic arc welding for maximum efficiency, a thorough analysis of data and metrics is essential. Recent studies indicate that companies implementing advanced data analytics can improve productivity by up to 25%. Capturing key performance indicators (KPIs) such as cycle time, downtime, and defect rates allows manufacturers to identify bottlenecks in the welding process. For instance, monitoring the arc length and travel speed can reveal inefficiencies that could be addressed through adjustments to programming or machine settings.

Moreover, leveraging real-time data from robotic systems can facilitate predictive maintenance, reducing unplanned downtime by as much as 30%. By assessing historical performance data coupled with machine learning algorithms, organizations can foresee potential failures and schedule maintenance proactively. Furthermore, analyzing the weld quality metrics through automated inspection systems enables continuous feedback loops, empowering operators to fine-tune processes dynamically and ensuring each weld meets the required specifications. This data-driven approach not only optimizes welding operations but also significantly enhances overall productivity in robotic arc welding applications.

Related Posts

-

Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry

-

Revolutionizing Metal Fabrication with Seam Tracking Welding Technology for Precision Parts Production

-

Why Robotic Welding Systems Are Revolutionizing the Manufacturing Industry Today

-

10 Essential Tips for Servo Robot Seam Tracking Success

-

What is Robotic Vision? Understanding Its Importance and Applications in Automation

-

Exploring the Future of Robotic Process Automation for Business Efficiency